0102030405

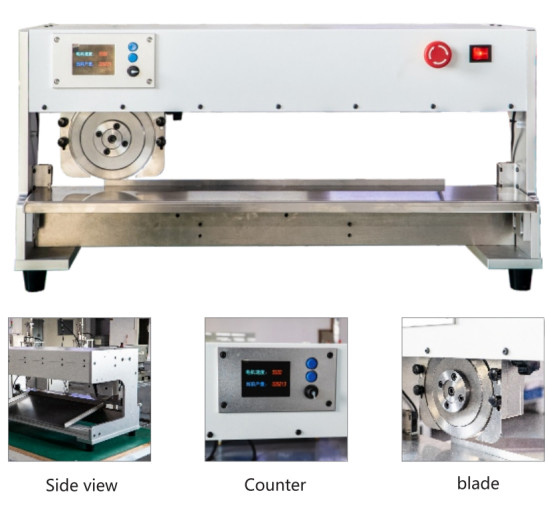

Cutting Board Splitter PCB Depaneling

01

7 Jan 2019

1. Cutter wheel travel stroke: 0-360mm (the tool length can be customized).

2. It can be equipped with a conveyor belt to facilitate automatic delivery of cut PCB boards.

3. The limit device can be applied to products of different sizes, thereby improving work efficiency.

4. The upper and lower knives are made of imported high-speed steel, which is extremely durable and can be ground again when the knife is in trouble.

5. Tailgate depth range: unlimited. Maximum plate cutting width: no limit, maximum plate cutting length: 360mm.

6. Using microcomputer program control, precise positioning and strong stability. Cutting off a single board within 0-360MM length with one knife

7. Lifting platform The lifting and lowering of the platform and the height of the platform can affect the quality of the product. It is not easy to cut the product and can also reduce the stress.

Technical Parameters

| Cutting Machine | RHHT-ZD360 | RHHT-ZD500 | RHHT-ZD600 |

| Machine specifications | 610*400*380MM | 750*400*380MM | 840*400*380MM |

| Maximum split board length | 330MM | 460MM | 560MM |

| Depaneling speed | 0, 120, 200, 400mm/second | 0, 120, 200, 400mm/second | 0, 120, 200, 400mm/second |

| Thickness of dividing board | 0.2-5mm | 0.2-5mm | 0.2-5mm |

| Operating voltage | 230V/50Hz (110V/60Hz) | 230V/50Hz (110V/60Hz) | 230V/50Hz (110V/60Hz) |

| Machine weight | 50kg | 55kg | 60kg |

| Packing size | 650*430*400MM | 650*430*400MM | 650*430*400MM |

| Packing weight | 68KG | 78KG | 88KG |

FAQ

Q: The knife hit the right side panel

A: 1. The right travel light sensor switch is broken and needs to be replaced.

2. Too much dust on the right travel switch will also cause collision. Just clean the dust.

Q: The knife hit the left side panel

A: 1. The left stroke light sensor switch is broken and needs to be replaced.

2. There is too much dust on the left travel switch. Just clean the dust.

Q: The motor rotates but the knife does not rotate.

A: The coupling jack screw is loose. Open the rear shell and tighten the jack screw.

Q: The indicator light does not light up after the power switch is turned on.

A: 1. Fuse segment, the fuse needs to be replaced

2. The emergency switch is not turned on.

Q: The itinerary is not accurate

A: 1. The stroke counter is broken and needs to be replaced.

2. There is too much dust on the stroke counter. Just clean the dust.