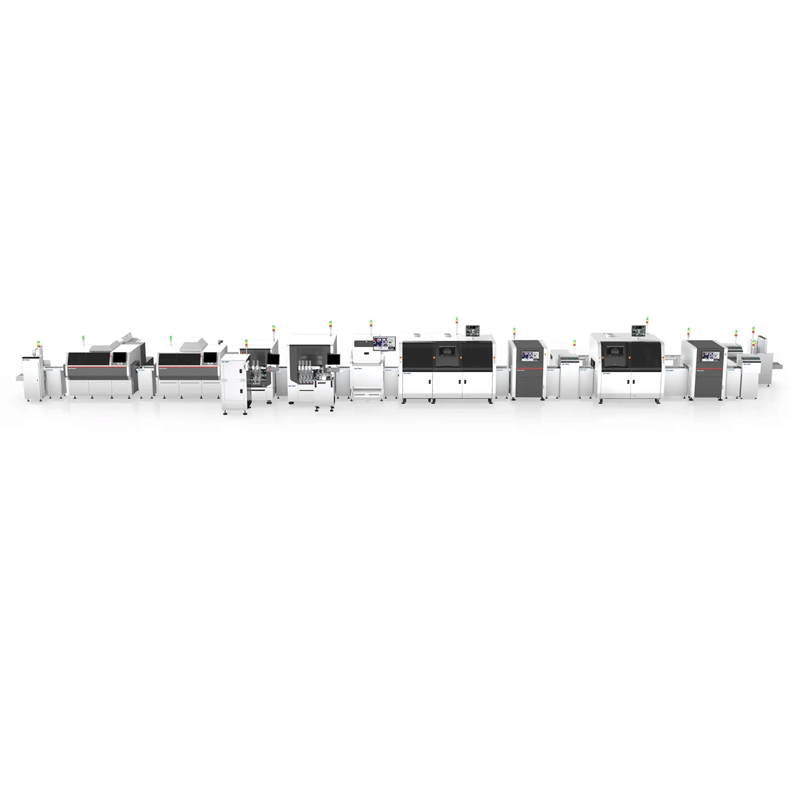

E by DEK - ASM Inline Solder Paste Printer

Features

E-Quality

DEK’s experienced printing specialists have developed an innovative platform for E by DEK with high-quality components, sophisticated construction, and modular design that guarantees a stable and reliable printing process even for the latest fine-pitch applications.

E-Performance

The E by DEK delivers E-Performance with:

8 seconds core cycle time

Fast setup changeovers

High repeatability

With the shortest cycle times and the fastest product changeovers paired with maximum repeat accuracy, the E by DEK sets new standards in the mid-speed segment.

E-Facts

Clearly structured, and each number provides a strong argument: The most important facts and figures on the E by DEK.

* Alignment qualifications include board loading/unloading, board clamping, camera/table movement. Capability value is calculated with 3rd-party QC-Calc software.

# Machine capability comprises board loading/unloading, board clamping, camera/rising table movement and print process. The capability value is calculated with 3rd-party QC-Calc software.

E By DEK

Flexibility at its best!

Each SMT factory has its own special challenges. That is why we have developed Options for the E by DEK that allow custom tuning with perfectly coordinated modules for printing results that will make your customers happy and raise your SMT production to a new level.

E by DEK Options for all your applications:

Throughput

Quality

Flexibility

Long and heavy circuit boards

|

Alignment |

> 2.0 Cmk @ ± 12.5 μm (± 6 sigma) |

|

System alignment capability |

> 2.0 Cmk @ ± 25 μm (± 6 sigma) |

|

Optimum core cycle time |

8 seconds |

|

Substrate size |

50 mm (X) x 40.5 mm (Y) to 620 mm (X) x 508.5 mm (Y) |

|

Operating System |

Windows 7 Embedded |

|

Squeegee pressure mechanism |

Software-controlled, motorized with closed loop feedback |

|

Stencil positioning |

Semi-auto stencil load with drip tray |

|

Understencil cleaning |

Interchangeable understencil cleaner (IUSC), fully programmable with wet/dry/vacuum wipe |

|

Adjustable-width stencil mount (AWSM) |

Frame variants - fully adjustable to accommodate frame sizes in the range of 381 mm to 736 mm |

|

Substrate thickness |

0.2 mm to 6 mm |

|

Substrate weight (maximum) |

6 kg |

|

Substrate warpage |

Up to 7 mm including substrate thickness |

|

Substrate fixture |

Over the top clamp Edge clamp Foil-less clamp Vacuum |

|

Temperature & humidity sensor |

Monitoring of the process environment |