0102030405

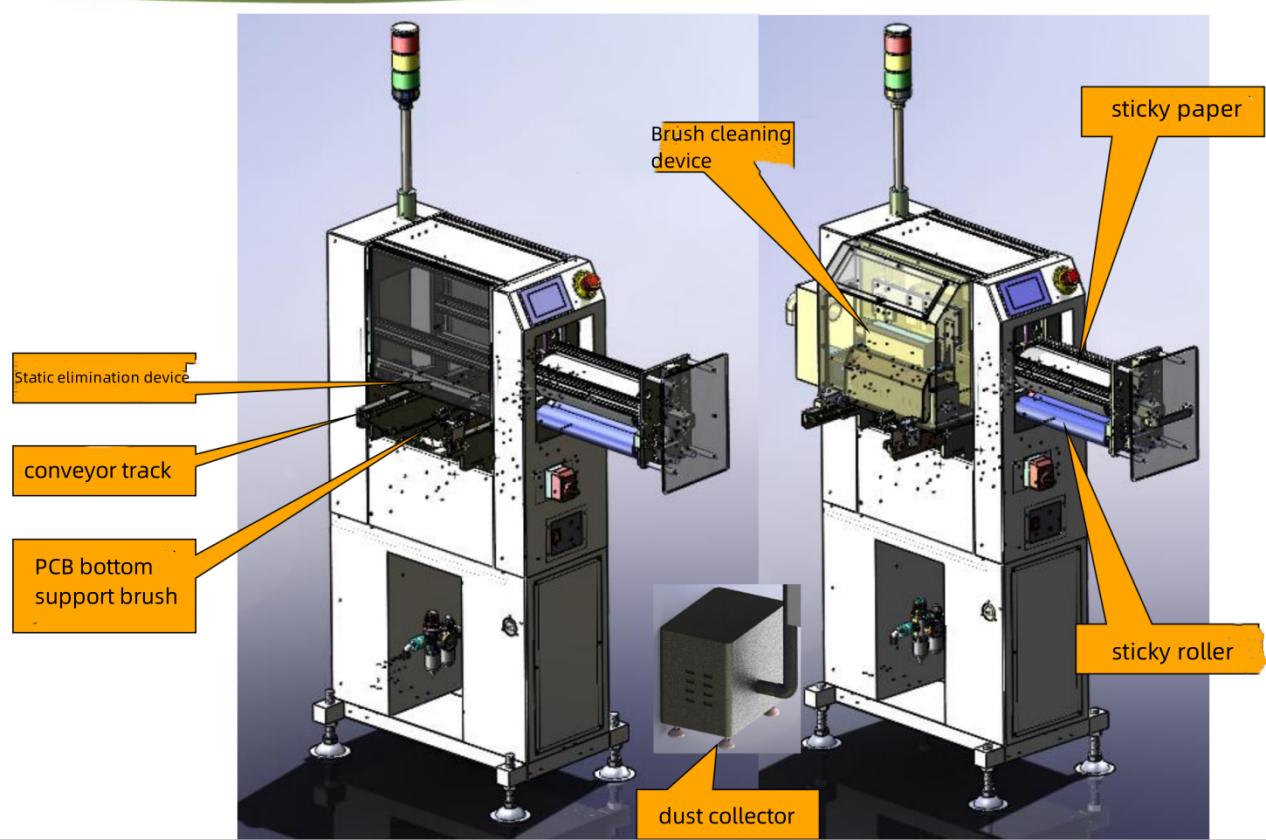

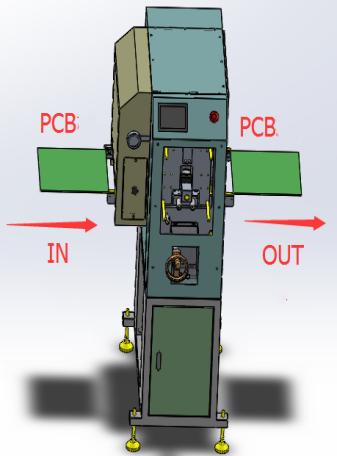

FR-3500 PCBA Automatic Cleaning Machine

Technical Parameters

| Technical Parameters | ||

| Project | FR-3500 Specifications/Parameters | Remarks |

| PCB dimensions | 50x50~300x300 (L*W*H)mm | Other models of large |

| substrates | ||

| correspond to | ||

| PCB thickness | 0.5~3.2mm | For special applications for |

| substrates of 0.4mm or less | ||

| Transfer height | 900±25 mm | |

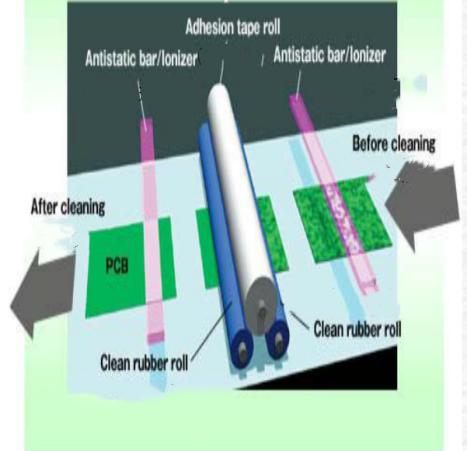

| Cleaning brushes | 1 root | |

| Vacuum suction unit | 1 set | |

| Sticky Dust Roller | Front and back | |

| Dusting paper | One volume | |

| Orbital direction | left → right or right → left | Optional |

| track fixing side | anterior or posterior fixation | Optional |

| track width adjustment | Manual | Automatic track width adjustment option |

| de-electrostatic devices | Built-in | Special de-static device optionally available |

| Air supply | 0.4-0.5MPa | |

| Power supply | AC220V,50HZ | Special voltages to be specified |

| Overall Dimension(mm) | 890X600X1400 | |

| Weight | 140KG | |

Details

FAQ

Q: Poor cleaning effect:

1. Check whether the concentration of the cleaning agent is correct and ensure that appropriate cleaning agents and solvents are used.

2. Check whether the cleaning nozzle or nozzle is blocked, clean or replace the defective nozzle.

Q: PCB residue or stains:

1. Ensure that the cleaning agent flows evenly and covers the entire PCB surface.

2. Check whether the nozzle or nozzle of the cleaning machine is intact and ensure even spraying. If necessary, use tools such as brushes or cotton swabs for spot cleaning.

Q: Accumulation inside the cleaning machine:

Regularly clean the inside of the cleaning machine, including the cleaning tank, pipes and nozzles. Check the filter system of the cleaning machine and clean or replace the filter.

Q: Cleaning machine failure or shutdown:

Check whether the power supply and power cord are properly connected to ensure stable power supply. If necessary, contact the equipment manufacturer or service personnel for repair and maintenance.