0102030405

FR-630 Automatic Spray Fixture Cleaning Machine

01

7 Jan 2019

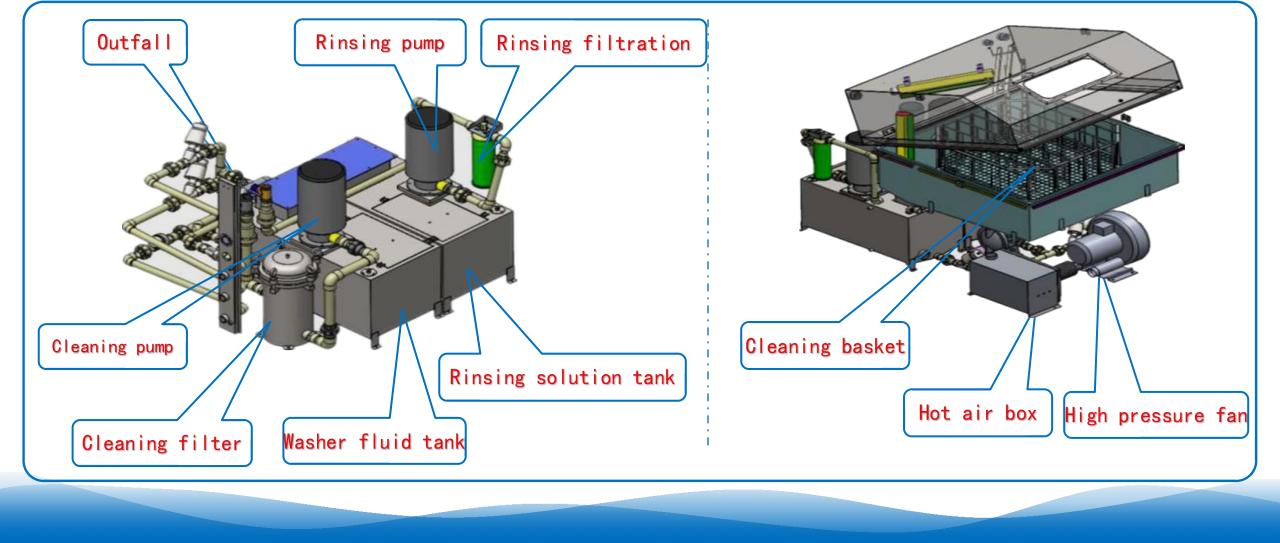

Cleaning system: During cleaning, nozzles are arranged at the upper, lower and side of the rotating cleaning basket. While the workpiece rotates, all cleaning nozzles spray cleaning fluid at high pressure to clean the workpiece in an all-round scanning manner. The cleaned cleaning fluid returns to the cleaning fluid tank for circulating filtration and heating.

01

7 Jan 2019

Rinsing system: During rinsing, nozzles shall be arranged at the upper, lower and side of the rotating cleaning basket. While the workpiece rotates, all rinsing nozzles shall spray pure water under high pressure to rinse the workpiece in an all-round scanning way. The residual cleaning liquid after rinsing shall be thoroughly washed. The rinsing liquid after rinsing shall be returned to the cleaning liquid tank for circulating filtration and heating.

Technical Parameters

| Technical Parameters | |

| Machine dimensions(mm) | L1800*W1550*H1500 |

| Voltage | 380V/50HZ(Three phase five wire) |

| maximum power | 27KW |

| Rated current | 30A |

| Air source | 0.4-0.6Mpa |

| source of water | 0.1-0.3Mpa |

| Air outlet | Ø125mm |

| Basket diameter | 1000mm |

| Maximum height of workpiece | 480mm |

| Work basket load | 100 KG |

| Pressure range | 3-8 KG |

| Tank capacity | 50L*2 It is recommended to add 40L (add detergent to the cleaning tank and add water to the rinsing tank) |

| Spray pressure | 3-6KG |

| Mass weight of complete machine | 480KG |

Details

FAQ

Q: How many pieces of fixture can be put in?

A: Depending on the size of the fixture, the quantity that can be cleaned each time will be different.The following empirical data can be used for reference:

| Fixturesize(mm) | placementquantity |

| 150x150 | 44 |

| 300x300 | 24 |

| 500x500 | 10 |

Q: How long will it take?

A: According to the frequency of fixture cleaning,the cleaning time set each time will be different.

Q: How long can the filter element last?

A: Depending on the size of the fixture, the quantity that can be cleaned each time will be different.

Q: After washing,it looks like it’s fluffy?

A: The fixture is made of synthetic stone and mainly consists of resin and high temperature resistant fiber. After the fixture is used for many times, the resin surface is carbonized at high temperature and falls off under the influence of flux. The fiber will not be affected. The surface of the fixture before cleaning is covered with flux, and the fiber cannot be seen or touched.After the fixture is cleaned, the flux is washed off,and the fiber is exposed. It feels fluffy.