0102030405

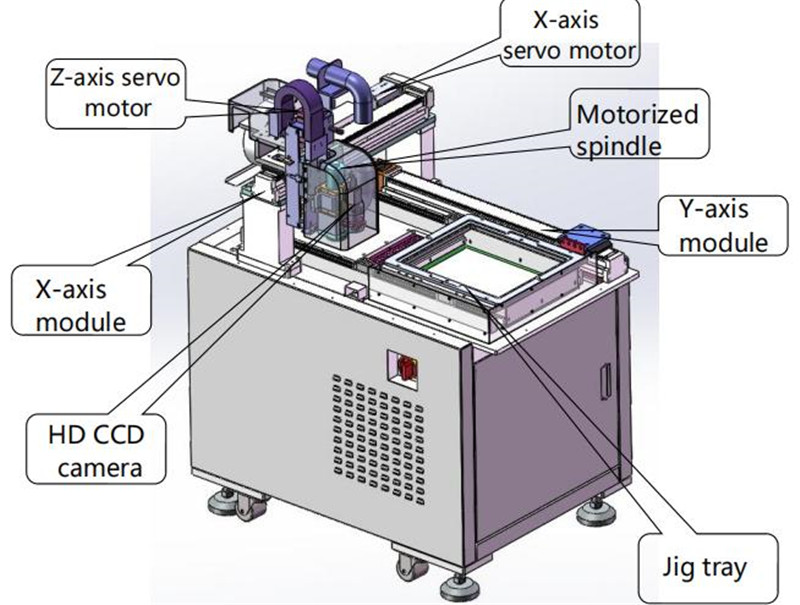

Fully Automatic Cutting RS-100N

01

7 Jan 2019

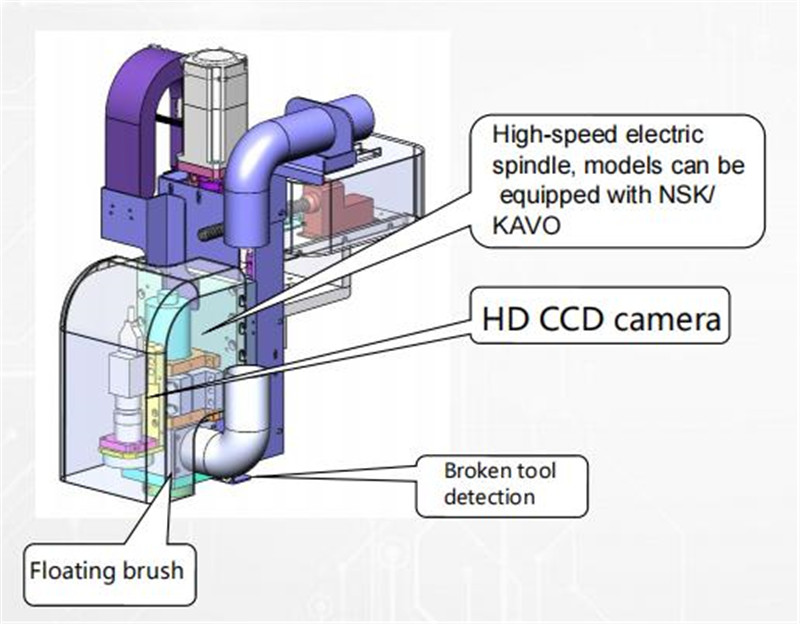

1. The equipment adopts a precision electric spindle. The NSK spindle speed can reach 60,000 rpm; the KAVO spindle speed can reach 80,000 rpm.

2. The Z-axis structure adopts automatic adjustment of camera height, so that products of different heights and different imaging heights can be used universally. At the same time, the Z-axis is equipped with a floating brush structure, and a lifting brush is used to take into account the depth of the knife. Reduce brush gaps.

3. Rich exterior structure interfaces. Can be equipped with broken knife detection, ion air gun, height detection, coaxial light source, floating brush, etc.

Technical Parameters

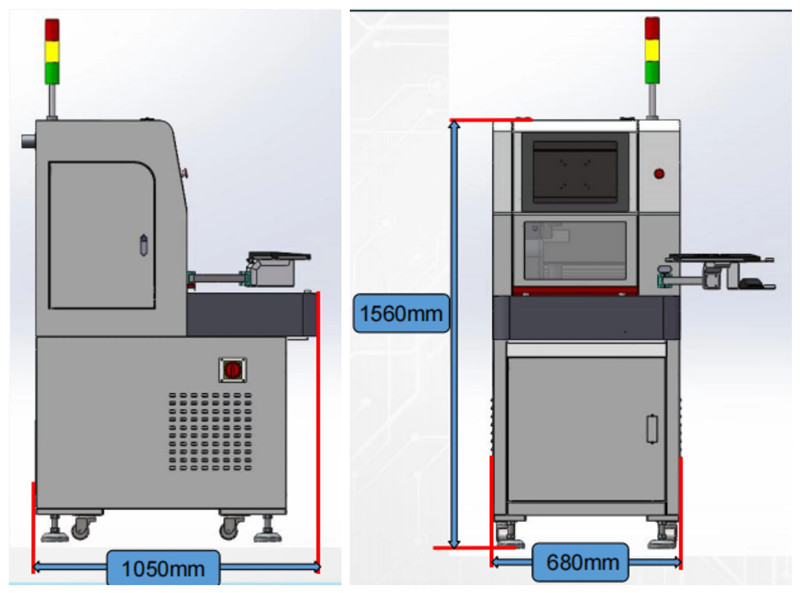

| Sing Table Visual Board Cutting Machine RS-100N | |

| Equipment size | W680*D1050*H1450 |

| Milling cutter replacement method | Manual/automatic tool change (optional) |

| Effective panel size | X350*Y380mm |

| Cutting speed | 1-100mmls adjustable |

| Worktop | single-platform |

| Operation interface | Window operation interface Windows 10 |

| Machine Repeatability | ±0.01mm |

| Programmed teaching method | Color CCD image visual teaching input |

| Cutting accuracy | ±0.05mm |

| Program backup | One-click restore |

| Maximum movement speed | XY:1000mm/s、Z:300mm/s |

| XYZ drive method | AC servo |

| Maximum moving range | X:385 Y:510 Z:100mm |

| Vacuum cleaner power | Suction up 4-6p, suction down 3-5p |

| Spindle speed | MAX.60000RPM adjustable |

Sing Table Visual Board Cutting Machine RS-100N

FAQ

Q: How to solve the problem of forward and backward movement of the left and right boards?

A: The driver is faulty and damaged; the driver control line is broken or detached.

Q: The software crashes when opening the initialization interface.

A: Check the position of the X/Y/Z origin sensor or whether it is damaged.

Q: The spindle does not rotate.

A: Check the power supply of the controller; turn the spindle gently by hand. If there is obvious resistance, the spindle is faulty; check whether the inverter is faulty or replace it with the same model.

Q: There is no image in the image area.

A: Check in the device manager. If there is a problem, please reinstall the driver; check whether there is an open circuit in the line; check whether the image channel hardware and software are both CH4.

Q: There is abnormal sound or vibration when the axis moves at high speed

A: Check in detail whether the screws at the joints of the faulty shaft are firm; the judgment can be made when the motor is under no load.