0102030405

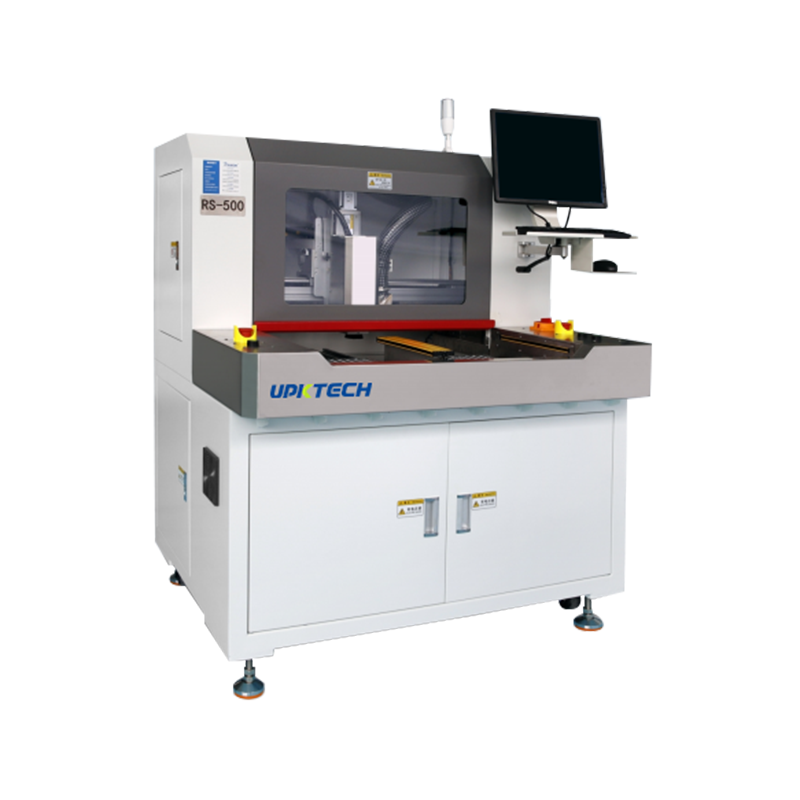

Fully Automatic Cutting RS-500

01

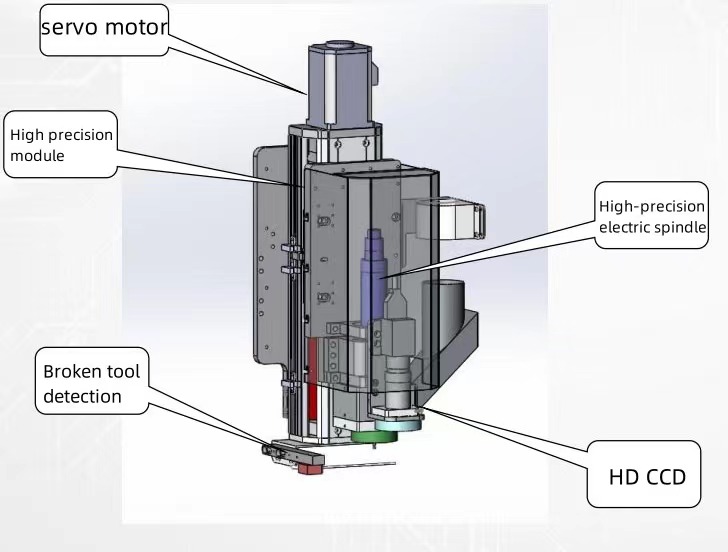

7 Jan 2019

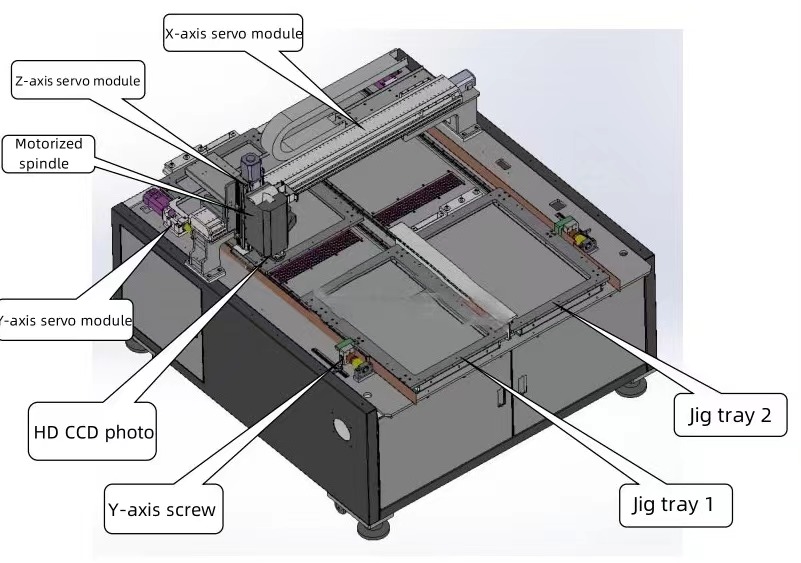

1. This equipment manually picks and places products, and double pallets alternately operate to separate plates;

2. The equipment has a mature structure, practical functions, stability and reliability, which improves efficiency and is more convenient for personnel to use.

3. The equipment has an automatic detection function for broken blades, which prevents continued operation after a broken blade and improves efficiency;

4. Equipped with a high-power, strong-suction dust collector to effectively remove dust generated during cutting;

5. The annular vortex static elimination and air separation mechanism is used to effectively remove the static electricity generated during cutting;

6. With alarm function and abnormal warning prompt;

7. The equipment's moving mechanisms are all connected reliably, and are designed with buffering and shock-absorbing mechanisms. Safety gratings are installed at the entry and exit positions of the pallets to ensure the safety of employees.

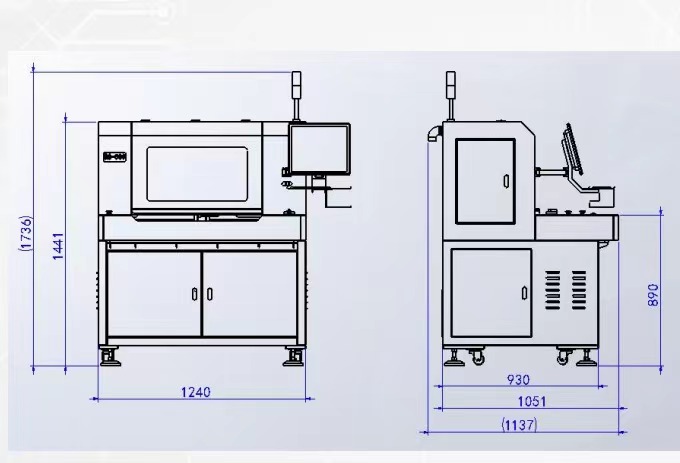

Technical Parameters

| Cutting Machine | RHHT-ZD360 | RHHT-ZD500 | RHHT-ZD600 |

| Machine specifications | 610*400*380MM | 750*400*380MM | 840*400*380MM |

| Maximum split board length | 330MM | 460MM | 560MM |

| Depaneling speed | 0, 120, 200, 400mm/second | 0, 120, 200, 400mm/second | 0, 120, 200, 400mm/second |

| Thickness of dividing board | 0.2-5mm | 0.2-5mm | 0.2-5mm |

| Operating voltage | 230V/50Hz (110V/60Hz) | 230V/50Hz (110V/60Hz) | 230V/50Hz (110V/60Hz) |

| Machine weight | 50kg | 55kg | 60kg |

| Packing size | 650*430*400MM | 650*430*400MM | 650*430*400MM |

| Packing weight | 68KG | 78KG | 88KG |

Double Table Visual Board Cutting Machine RS-500

FAQ

Q: The software crashes when opening the initialization interface.

A: Check the position of the X/Y/Z origin sensor or whether it is damaged.

Q: The static eliminator is faulty, please notify the technical personnel.

A: 1. Turn off the power and turn it on again.

2. Connect the line securely.

3. Please replace with new products.

Q: Left and right table plate advance and retreat failure

A: 1. Drive failure and damage.

2. The driver control cable is loose.

Q: There is no image in the image area

A: 1. Check in the device manager. If there is a problem, please reinstall the driver.

2. Check whether the circuit is open or not.

3. Check whether the image channel hardware and software are both CH4.

Q: Cutting accuracy decreases

A: 1. Reset the tool/CCD center coordinates.

2. Check whether there is too much dust on the camera lens or the product surface, whether the product is placed stably, and whether the height from the camera to the product surface has changed.

3. Check whether the positioning pins and fixtures are loose or not.

4. Check and tighten.