0102030405

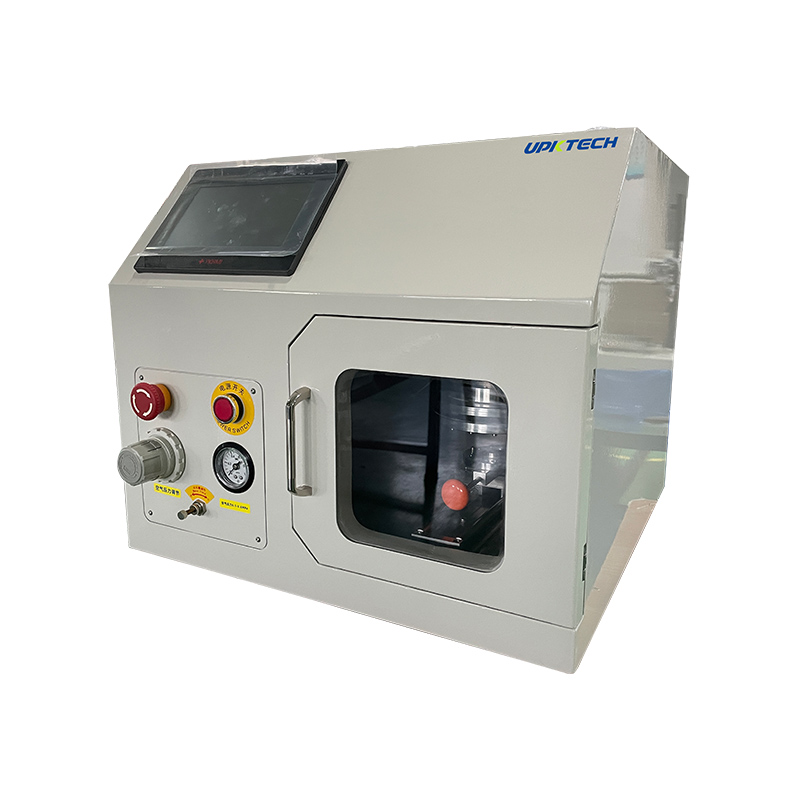

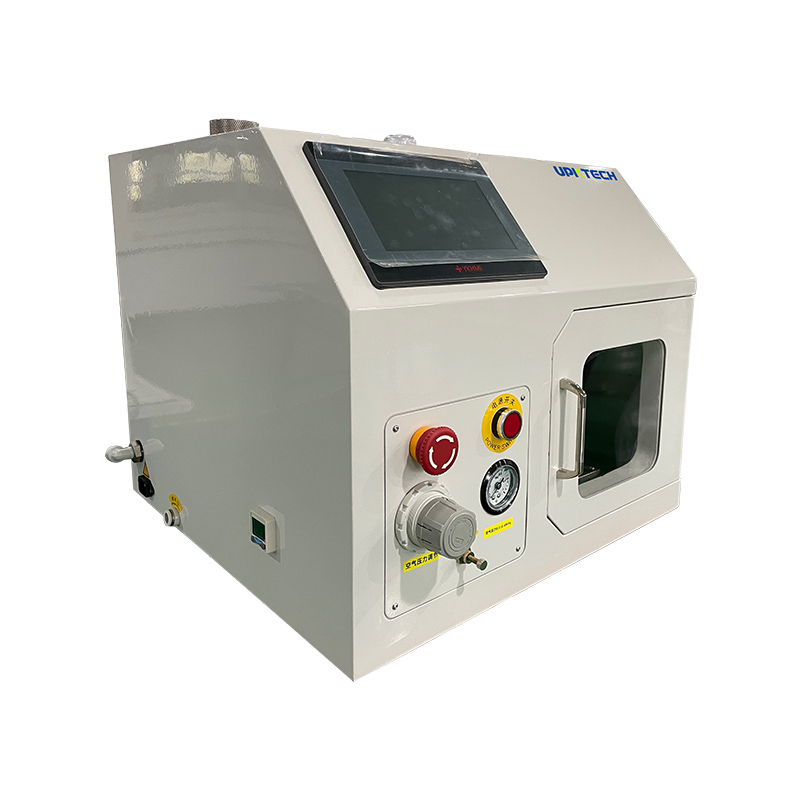

Fully Automatic Nozzle Cleaning Machine

01

7 Jan 2019

The appearance adopts a streamlined design, beautiful and elegant; the full inspection window is convenient for maintenance and operation; the parts in contact with water are all made of 304 stainless steel, which is rust-proof, anti-corrosion, strong and stable; the humanized design can realize one-click activation on the external button and touch screen + PLC distributed control, stable and reliable performance; easy to operate, friendly interface and can switch between Chinese and English at any time; equipped with malfunction alarm and emergency braking system, equipped with overload protection system; added water level sensing function.

Technical Parameters

| Technical Parameters | |

| Equipment size | 540 ×570 ×530MM |

| equipment weight | 62KG |

| Nozzle specifications | 0201-2125 |

| Air pressure | 0.5-0.6Mpa |

| Air consumption | 280NL/min or less |

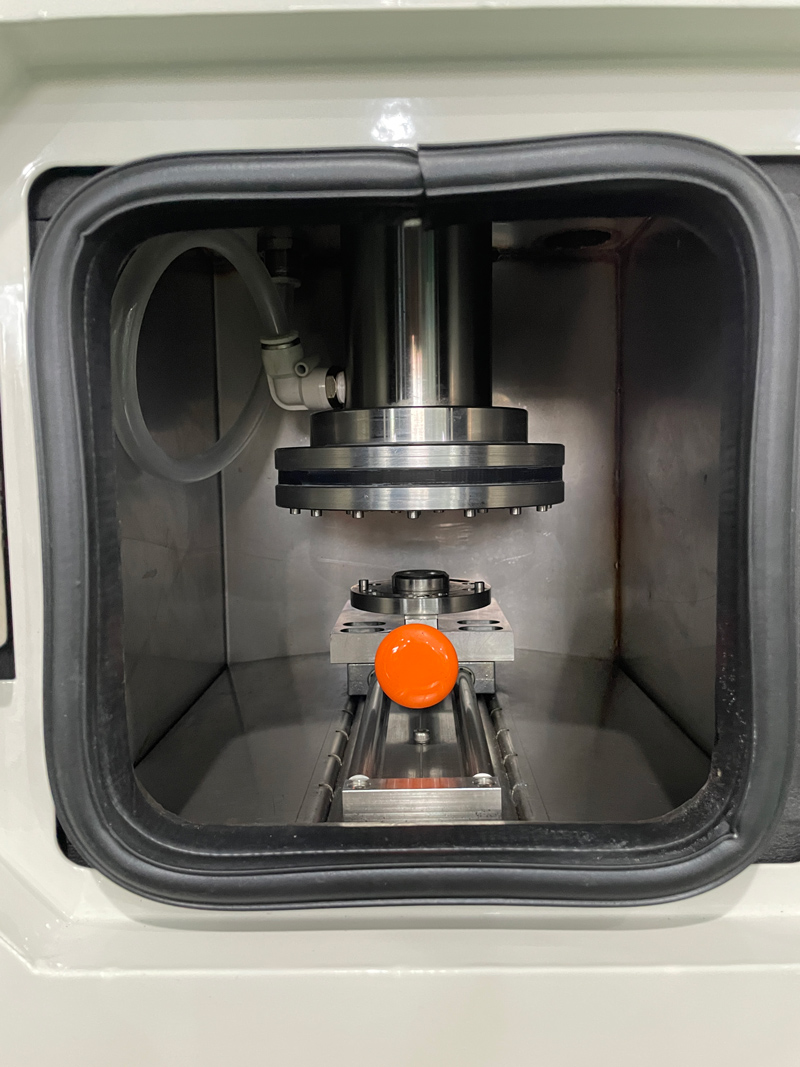

| Pallet specifications | 32 bits |

| Rated voltage | (optional) AC110V AC220V |

| Cleaning time | 200 seconds/time |

| cleaning liquid | Industrial pure water |

| Display function | touch screen, digital pressure gauge, pointer pressure gauge |

| Drive motor | 86 high-precision stepper motor |

| Liquid level detection | high and low water level alarm |

| Start mode | soft start to protect motor bearings |

| Interface login | administrator password login |

| Protection measures | Highly sensitive leakage protection switch, safety door, emergency stop switch |

| Product certification | 3C, CE certification |

| Material | All parts in contact with water are made of high-quality SUS-304 material |

| Alarm mode | sound and light alarm, interface prompts |

| Wastewater collection | centralized collection at the water outlet |

Details

FAQ

Q: The cleaning effect is not good and the residue is difficult to remove?

A: Increase cleaning time or use more powerful cleaning fluid.

Q: Are suction nozzles frequently lost or damaged?

A: Strengthen the screening filter and use a nozzle clamp or special rack to make it easier to access.

Q: Is the cleaning machine noisy when running?

A: Check whether the transmission device is loose or worn. Consider a shock-absorbing design or replacement of a low-noise pump.

Q: Is the cleaning time too long and the efficiency low?

A: Adjust cleaning parameters and strengthen spraying. The program can be optimized to automatically control the cleaning cycle.

Q: Will there be corrosion or rust after cleaning?

A: To eliminate metal ions, choose stainless steel and maintain it regularly to prevent rust.

Q: Other hardware issues?

A: Timely replacement of parts such as motor aging and bearing wear, etc., and regular maintenance.