GKG GT++ Fully Automatic Solder Paste Printer Used / New

Introduction

- Drip cleaning system

Drip cleaning structure effectively prevents the solvent tube from blocking the hole and causing the local solvent-free and unclean wiping.

- Brand-new scraper structure design

The new scraper structure of the slide rail and cylinder improves the operation stability and extends the service life.

- Guide rail positioning system

International utility model invention patent. The detachable and programmable flexible side clamp device performs unique top flattening for soft boards and warped PCBs. It can be automatically retracted through software programming without affecting the tin thickness.

- CCD digital camera system

The brand-new optical path system-uniform annular light and high-brightness coaxial light, with infinitely adjustable brightness function, makes all types of Mark points can be well identified (including uneven Mark points) to adapt to tin-plated, copper-plated, gold-plated, tin-sprayed, FPC and other types of PCBs of different colors.

- High-precision PCB thickness adjustment lifting platform

Compact and reliable structure, stable lifting and lowering, PIN height software automatic adjustment, can accurately adjust the position height of PCB boards of different thicknesses.

- New multi-functional interface

Simple and clear, easy to operate. Real-time temperature remote control function.

- Bottle-type automatic tinning and solder paste detection function

Mobile automatic solder paste addition to ensure solder paste quality and solder paste amount in steel mesh, thereby ensuring customer printing quality and improving productivity.

- Automatic glue dispensing system

According to different printing process requirements, after printing, the PCB board can be accurately dispensed, tinned, line drawn, filled and other functions; at the same time, the glue dispensing head is also equipped with a heating function, which can heat the glue when the ambient temperature is low to improve the fluidity of the glue.

- SPI connection

Connected with SPI to form a closed-loop system. When receiving feedback information about poor printing from SPI, the machine will automatically adjust according to the SPI feedback offset. The XY direction offset can be automatically adjusted within 3PCS, and the steel mesh will be cleaned to improve printing quality and production efficiency, forming a complete printing feedback system.

- Steel mesh detection function

By performing light source compensation above the steel mesh, using CCD to check the mesh of the steel mesh in real time, it can quickly detect and determine whether the steel mesh is blocked after cleaning, and automatically clean it, which is a supplement to the 2D detection of the PCB board.

- Leading the compatibility of Industry 4.0

By automatically uploading or outputting the machine status and parameters, it provides strong guarantees for the intelligent production of Industry 4.0 for customers. It can achieve seamless docking with the customer's MES system and achieve high traceability of products; intelligently control equipment maintenance, and realize self-allocation of usage rights for engineers at all levels according to on-site management.

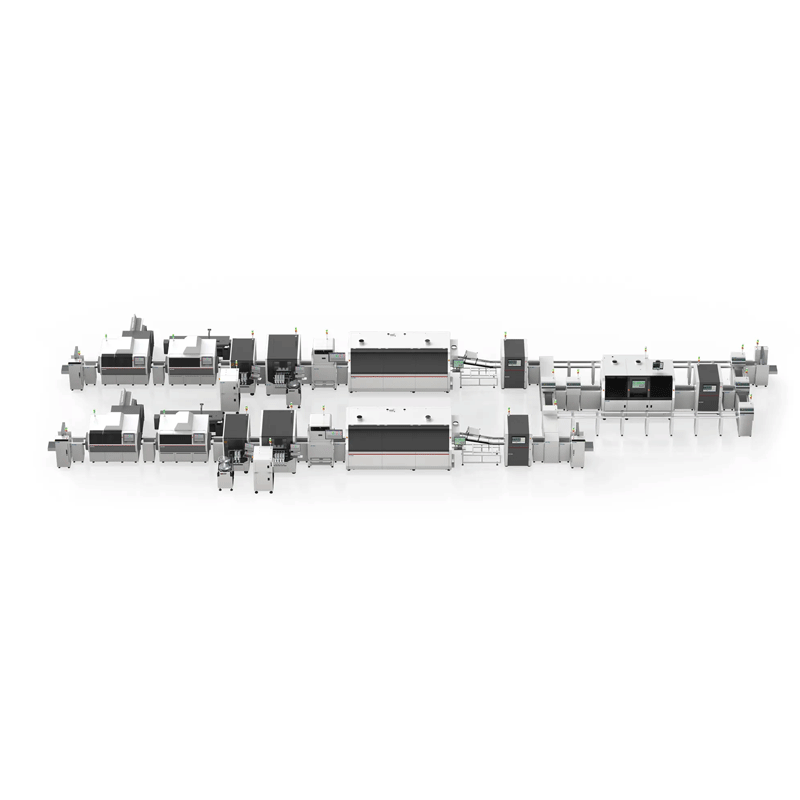

- BTB

Double tracks bring twice the performance: the two devices can be controlled separately, for example running different products on each track; the two devices can be separated again at any time.

|

Model |

GT++ |

|

Screen frame size |

470×370-737×737mm |

|

Substrate size |

50×50—510×510mm |

|

Substrate thickness |

0.4-6mm |

|

Substrate weight |

5Kg |

|

Substrate edge gap |

2.5mm |

|

Transmission height |

23mm |

|

Transmission height |

900±40mm |

|

Transport speed |

1500mm/S (MAX) Software control (speed adjustable) |

|

Transmission method |

One-stage transport guide rail |

|

Substrate support method |

Magnetic ejector pin/equal height block/automatic adjustment of lifting platform |

|

Substrate clamping method |

Automatic telescopic upper pressure plate/flexible clamping edge/vacuum adsorption function |

|

Printing demolding |

0-20mm |

|

Printing mode |

Single or double scraper printing |

|

Scraper type |

Rubber scraper/steel scraper (angle 45°/55°/60°) |

|

Scraper speed |

6-200mm/sec |

|

Printing pressure |

0.5-10Kg |

|

Cleaning method |

Drip cleaning system/reciprocating cleaning/dry and wet vacuum modes |

|

Field of view |

10×8mm |

|

Reference point type |

Standard reference point/pad/opening |

|

Camera type |

Visual system with up and down imaging/digital camera/geometric matching positioning |

|

System alignment accuracy and repeatability |

±12.5um@6σ, CPK≥2.0 |

|

Actual solder paste placement repeatability |

±18um@6σ, CPK≥2.0 |

|

Printing cycle |

<7.5sec |

|

Power requirement |

AC220V±10%,50/60Hz,3KW |

|

Compressed air requirement |

4-6Kgf/cm² |

|

Air consumption About |

5L/min |

|

Working environment temperature |

﹣20℃~﹢45℃ |

|

Working environment humidity |

30%~60% |

|

Dimensions (excluding three-color light) |

L1240×W1410×H1500 (mm) |

|

Weight |

About 1100Kg |