0102030405

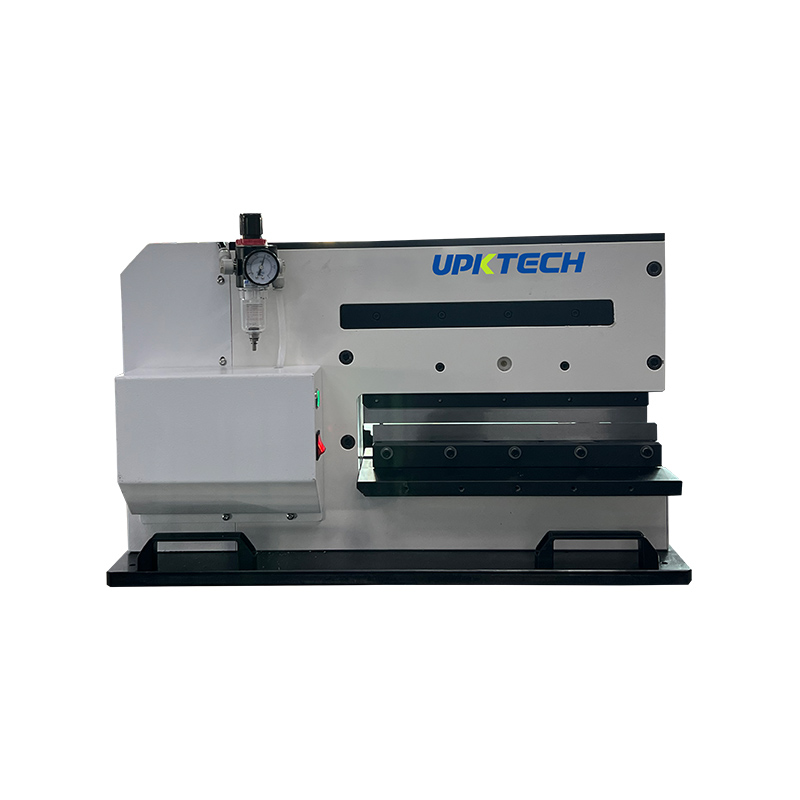

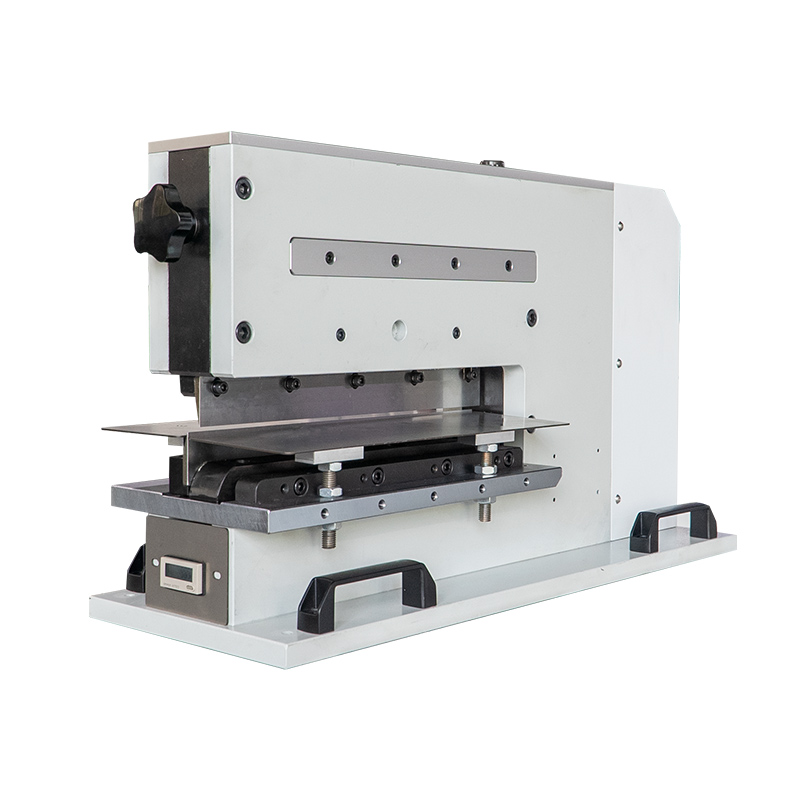

Guillotine Type Plate Splitting Machine

01

7 Jan 2019

1. After the tool is worn, it can be reground for free.

2. Double straight knife slitting, especially suitable for cutting precision SMD thin plates and aluminum circuit boards.

3. Use 5-7KG air pressure, no specific cutting place is required; just wipe the appearance with anti-rust maintenance oil.

4. Reduce the internal stress generated during board cutting to less than 180uE to avoid tin cracks and damage to precision parts.

5. Non-roller (wheel knife, knife feed) cutting, no dust, no motor drive, no toner pollution.

6. The cutting knife group is passively activated, which can safely control the cutting line and position; the cutting stress is small and it is not easy to form cracks.

7. Guillotine-style work, suitable for PCBs of various thicknesses. The cutting stroke is less than 1-2mm, so there are no concerns about operational safety.

Technical Parameters

| Technical Parameters | |

| Maximum panel length | 360MM |

| Overall dimensions (length × width × height) | 700 × 270 × 460mm |

| Board thickness | 0.2-5mm |

| Working air pressure | 0.50-0.70Mpa dry air source |

| Operating voltage | 230VA |

| Machine weight | 136kg |

FAQ

Q: The indicator light does not light up after the power switch of the guillotine PCB depaneler is turned on:

A: 1. Fuse segment, the fuse needs to be replaced

2. The emergency switch is not turned on.

Q: The stroke of the guillotine PCB depaneler is not accurate

A: 1. The stroke counter is broken and needs to be replaced.

2. There is too much dust on the stroke counter, just clean the dust.

Q: The knife of the guillotine PCB depaneler hits the left side panel

A: 1. The left stroke light sensor switch is broken and needs to be replaced.

2. There is too much dust on the left travel switch. Just clean the dust.

Q: The knife of the guillotine PCB depaneler hits the right side panel

A: 1. The right travel light sensor switch is broken and needs to be replaced.

2. There is too much dust on the right travel switch. Just clean the dust.

Q: The motor of the guillotine PCB depanel machine rotates, but the knife does not rotate.

A: If the coupling jack screw is loose, open the back shell and tighten the jack screw.