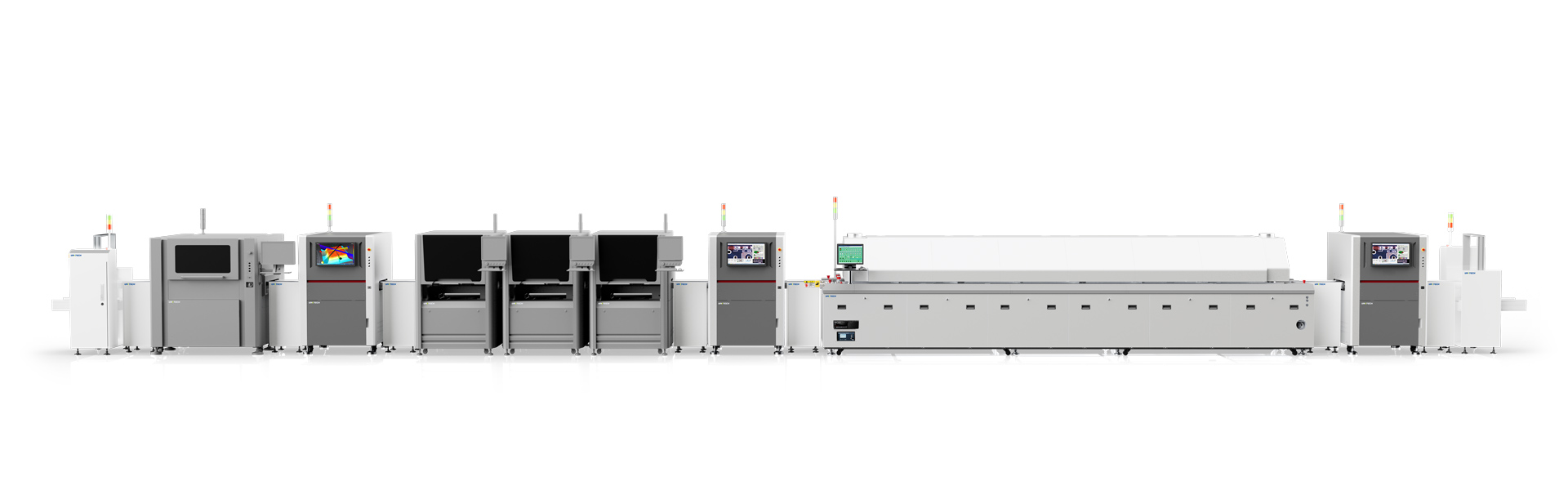

RADIAL AUTO INSERTION MACHINE NB-168

NB168 H&M Series

NB168 H&M-2P 2-Pitch Insertion Machine(2.5/5.0 mm)

NB168 H&M -3P 3-Pitch Insertion Machine(2.5/5.0/7.5mm)

NB168 H&M-4P 4-Pitch Insertion Machine(2.5/5.0/7.5/10.0mm)

NB168 H&M-3.5P 3.5-Pitch Insertion Machine(2.5/5.0/3.5mm)

NB168 H&M -T4P Special4-Pitch Insertion Machine(2.5/5.0/7.5/10.0mm)

light industry

Household appliances industry

Automotive industry

The current automotive trend is intelligent automation, such as electric seats, electronic handbrakes, shift paddles, etc.

Other industries

Electronic solutions for other industries: electronic watches, instruments, electronic parts, etc.

Parameters

|

No. |

Item |

Content |

|

1 |

Power Supply |

Rated voltage:33-phase380V±20V |

|

Frequency:50/60Hz |

||

|

Rated power:Approx.3.5KVA |

||

|

2 |

Air supply |

Supplied air pressure:Min.0.45Mpa - Max.0.8Mpa(Operation air pressure0.45MPa~0.5MPa) |

|

Supplied air mass:Approx.110L/min.(A.N.R) |

||

|

3 |

Dimensions |

W:2134mm,D:1815mm,H:1600mm(Not including signal tower) |

|

4 |

M a s s |

Host weight:Approx.2,000kg(Main body only) |

|

5 |

Environmental requirements |

Ambient temperature:20℃±10℃ |

|

6 |

Operating controls |

Interactive operation via color LCD touch screen. |

|

Input and output functions 1/0 functions: USB slot (standard equipment) |

||

|

Communication:LAN communication(TCP/IP) |

||

|

7 |

Insert beat (speed) |

Max speed takt time: Approx0.14s/point(0.168,0.20,0.25,0.30s/point changeable |

|

8 |

Applicable components |

Height:Hn=Max23mm(Special specification up to 26mm) |

|

9 |

PCB replace time |

Diameter:D=Max . 13mm |

|

Resistors, electrolytic capacitors, ceramic capacitors, LEDs, transistors, filter resistor networks |

||

|

Approx.3~4 seconds |

||

|

10 |

Applicable PCB |

Dimensions:Min . 50mm×50mm~Max . 508mm×381mm |

|

11 |

Insertion direction |

Allowable insertion area:Min.50mmx40mm~Max.500mm×375mm |

|

Thickness:1.6mm±0.15mm(for standard specification)Min.0.6mm~Max2.0mm(Optional) |

||

|

Board weight:Max.1kg per board including inserted components. |

||

|

Flow direction:right→left(Standard)、left→right(Option) |

||

|

Board positioning method:Pin positioning or Edge positioning |

||

|

Board transfer:Single PCB transfer(Standard) Double PCB transfer(Special specification) |

||

|

360 degrees by 1 degree |

||

|

12 |

Anvil |

Lead bending angle 30°±15; Leading dimensions1.5±0.3mm; Cutting & Clinch type system (Piezoelectric detection system) |

|

13 |

No.of component inputs |

40/20 type inputs |

|

14 |

Control system |

Microcomputer system |

|

15 |

Programming method |

X-Y axes:Absolute coordinate commands |

|

Insertion pitch: Absolute commands |

||

|

Component feeder:Feeder number designation |

||

|

16 |

Least increment of X-Y table |

0 . 01mm/Pulse |

|

17 |

Program |

Number ofNC programs |

|

Built-in flash memory; 2000 programs |

||

|

USB Disk Depending on USB disk memory |

||

|

18 |

Indication light |

Signal tower (3 lamps,topto bottom:red/yellow/green) |

|

19 |

Hole position offset |

Determines optimum insertion positions based on the recognition of all insertion positions to make positionalcorrections(XYcorrection). |

|

20 |

Recovery |

Auto recovery/Auto recovery (Estimated Auto-recovery time Approx.12s) |

|

21 |

Self-diagnosis function |

Presents on the color LCD the machine status when the power is ON and situation of any troubles occurred,as well as countermeasures against the troubles |

Product Advantages

n The machine is fundamentally designed with an integrated casting process to ensure overall reliability, and with high-precision machining components, it ensures the long-term stability of the machine at high speeds.

n The core components are configured with world-renowned brands, X, Y and motion screws are all made of Japan THK, bearings NSK, servos and servomotors are all made of Japan Panasonic, ensuring the stability, durability and reliability of the core components.

n The cam-type structure mechanical movement principle is adopted, from feeder feeding, parts shaping, foot cutting, material transmission, material clamping, material pressing, foot cutting, the machine's repetitive accuracy is ensured.

n The high-precision integrated miniaturized feeder has a small size, high speed, low noise, self-contained material shaping, reduced material consumption, and is equipped with up to 40 stations for high efficiency.

n Cam foot cutting device , component shaping design improves the quality of component insertion, ensures efficient and stable insertion rate, low noise, durable tools,

n Original imported belt and tray clamp design from Japan, fast running speed, wear-resistant and durable, more stable clamping

n The force of each tool is consistent to ensure the integrity of the internal components. The maximum cutting line can be 0.8mm, and the foot cutting tool is reliable and durable

n Automatically detect component height and automatically generate program data during the first production to ensure a stable insertion rate

n Highly integrated system bus servo control layout, faster response speed, self-diagnosis of faults, direct and clear adjustment of main control interface parameters, and after-sales remote control assistance

n Simple and easy-to-understand operation interface, MES port docking, traceability management system

n Front and rear dual-screen display control to reduce the time of walking back and forth and improve efficiency