0102030405

01

view

detail

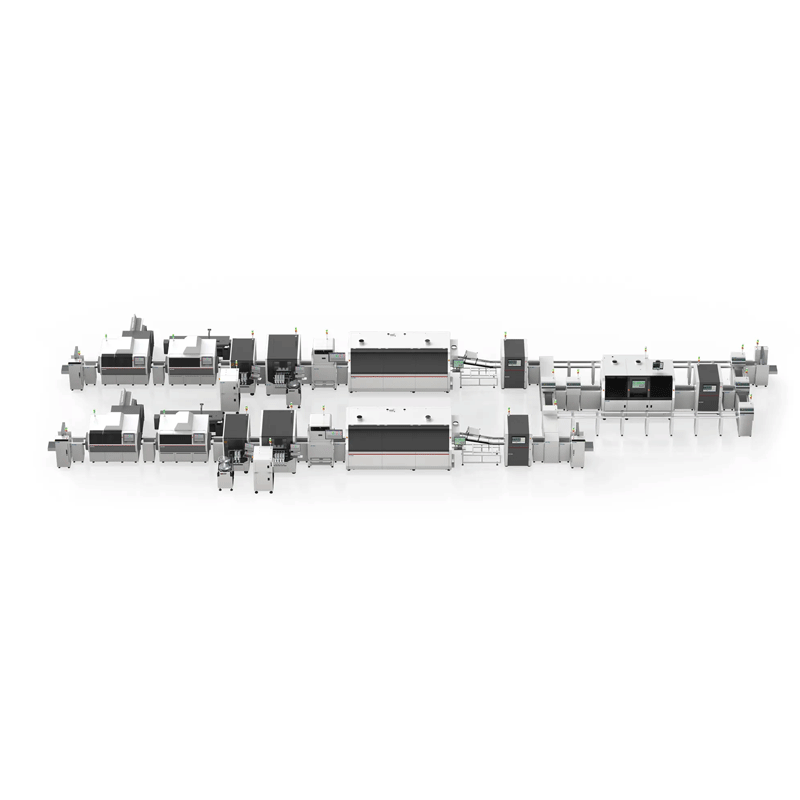

JTR Series JT Lead-Free Hot Air Reflow Oven

2024-09-20

Introduction

- Reinforced main hanging bracket to avoid rail deformation and board jamming;

- Multi-layer thermal insulation design. The Surface temperature of the Oven body is reduced by

- 10 to 20 degrees, reducing the temperature of the working environment effectively;

- New cooling configuration to make the fitered or reclaimed air back to oven chamber, it can

- reduce the thermal loss as well as get better flux collection;

- 15% heat transferring efficiency was improved to deal with the lead free process with more

- complicated and larger products;

- The dual-rails conveyor is able to improve the production efficiency as well as save power and

- cost;

- Use the full protection of the sealed oven design to prevent nitrogen losing. So the lowest

- concentration ofoxygen can be reached to 150ppm;

- Nitrogen consumption is only20-22M/H with the oxygen level 300-800ppm;

- Nitrogen closed-loop control system is optional, energy saving and environmental protection.

01

view

detail

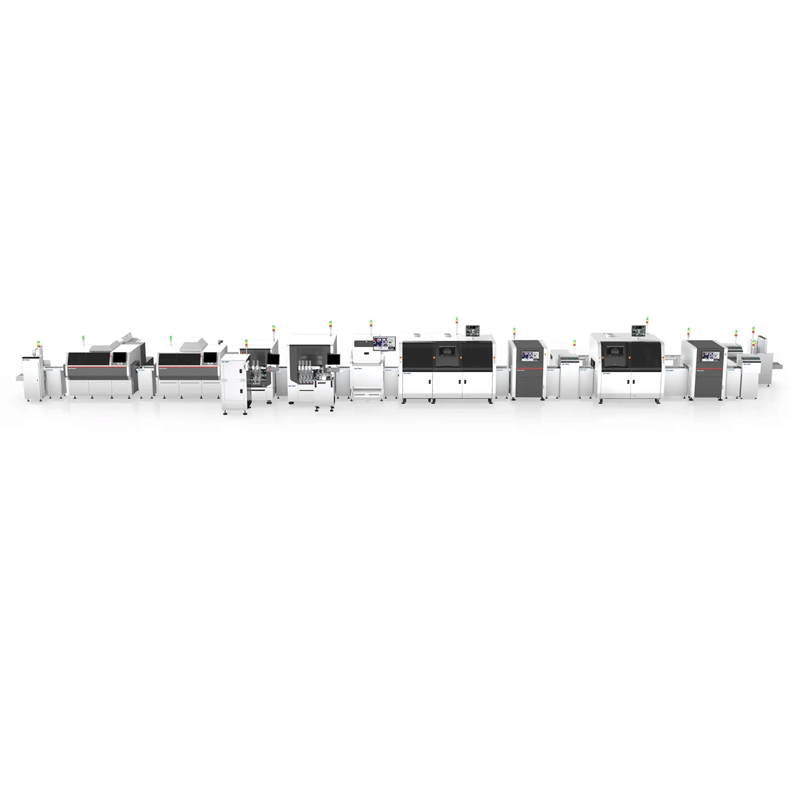

KT Series - High-End Lead-Free Hot Air Reflow Oven

2024-09-20

Description:

- Highcapacity, normal working conveyor speed reached160cm/min. Low energy consumption, low cost. Special for the high-speed production and high density PCBA technology;

- Powerful temperature control, setting and actual temperature difference within 1.0℃, unload and load temperature fluctuates within 1.5℃; Rapid temperature raising ability, temperature difference between neighboring zone 100℃;

- The newest insulation technique and new chamber design ensured that surface temperature is room temperature +5C;

- N²quality controllable in whole process, O² density closed-loop controlled independently at 50-200ppm in every zone;

- The newest cooling technology, optional double side multi-cooling zone, the effective cooling length is 1400mm, make sure fast cooling of the product to the lowest output temperature;

- New two level flux separation system with multi-zone collection which make separation thoroughly, so that the maintenancetime and frequency was reduced significantly;

- Dual line in different speed, one set cost, double capacity, energy saving 65%.