0102030405

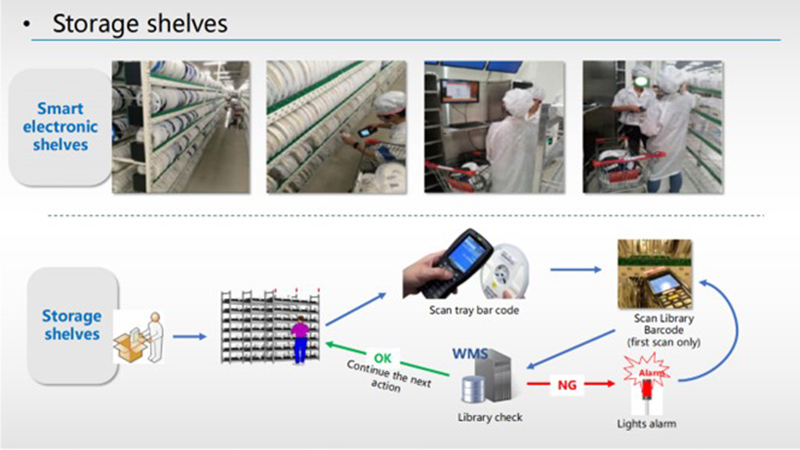

UPKTECH 1400S Smart Storage Rack

01

7 Jan 2019

● Efficient entry and exit, error prevention and foolproofing, the entry and exit efficiency is increased by 70%.

● High-capacity storage, saving 60% of storage area.

● High-precision, self-calibrating sensor accurately records the location of materials, and the accounts are consistent.

● Real-time docking with ERP&MES system.

● First in, first out, fully intelligent management, real-time management and control of overdue and sluggish services.

Application

Technical Parameters

| Technical Parameters | |

| Product Description | Can store 1400 trays of 7-inch electronic materials, 7 layers (thickness of tray 16mm); |

| Body size | 2240*400*1950mm |

| Material | SPSS carbon steel |

| Color | White (can be customized) |

| Power supply | AC 220V 50Hz |

| Rated power | 160W |

| Communication method | RJ45 network port+WiFi |

| Single layer load bearing | ≤100Kg |

| Mobile material rack (car) | Have |

| A fixed way | Fuma wheel level adjustment |

| Anti-static measures | Main body anti-static paint + soft light lamp beads. |

| Working environment | -20~+40 ℃ /10%~90%RH |

| Voice broadcast | Have |

FAQ

Q: What to do if the shelf has an abnormal red light on?

A: Scan the device number on the warehousing interface, click on the three small dots in the upper right corner to clear errors.

Q: What to do if the shelf has an abnormal green light on?

A: Materials that have not been reviewed when leaving the warehouse require an administrator to process them. In the software material removal module, select the removal type and select the storage location. Manually enter the flashing storage location, click Remove, and unbind the changed storage location. Remember to review and clear the materials after taking them out. lamp.

Q: The shelf does not light up and does not respond when touched?

A: Restart the shelf, check whether the shelf is powered on, and check whether the server is started.

Q: What are illegal and prohibited operations?

A: The sensor cannot occupy water, the terminal behind the sensor cannot be pulled out, and materials cannot be forced into or pulled out!