01

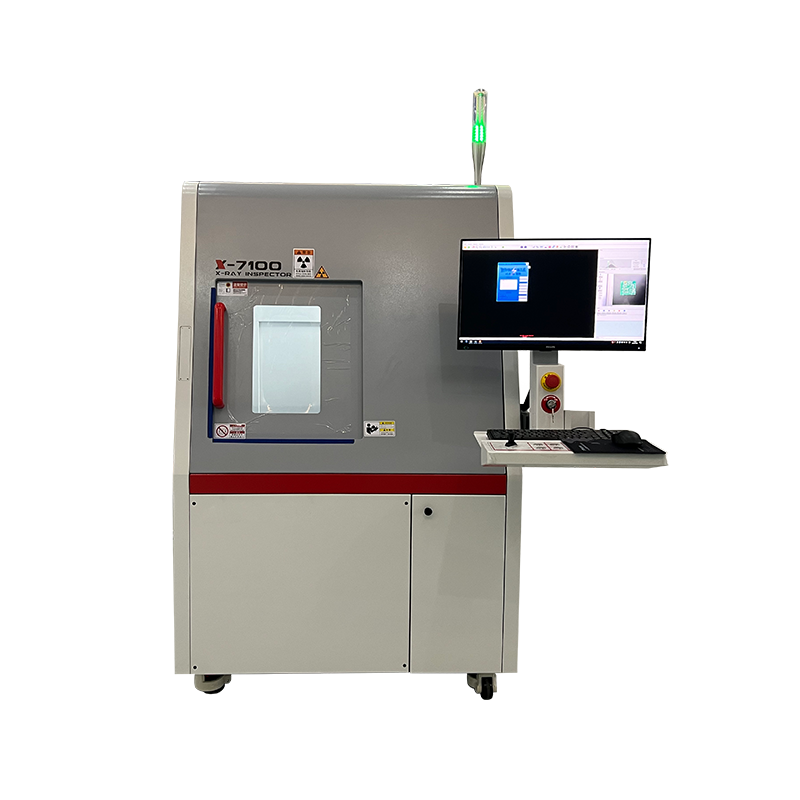

UPKTECH-850D Online Dispensing Machine

01

7 Jan 2019

1. The equipment can choose the offline operation mode of in and out in the same direction and the online operation mode of left in and right out, providing one-click change function for the trial production stage and subsequent online upgrades.

2. The main movement of the dispensing body is X, Y, Z, U, R five-axis movement, which can accurately realize the selective dispensing process of various circuit boards to avoid non-dispensing areas such as connectors. The two-axis control double step conveying method can Steplessly change the conveying speed, improve work efficiency and slow down the intensity of plate loading; computer control automatically adjusts the width of the conveying guide rail, a total of eight axes are card controlled, all axes can be linked to each other, and the function is powerful.

3. It can realize multi-track spraying such as dot coating, linear spraying, and curved spraying, and can complete the dispensing process of high-density and complex circuit boards, and can effectively realize the dispensing process at the pins of special-shaped components.

Technical Parameters

| UPKTECH-850D | |||

| Function configuration | Technical parameters and description | Function configuration | Technical parameters and description |

| Equipment model | HP-850D | Conveying height | 910±20mm |

| Equipment Dimension | L=1060mm W=1300mm H=1700mm | Conveying speed | 2-25m/min |

| Equipment weight | Approx.850kg | Conveying track | Special hard aluminium alloy track + stainless steel chain with edge stopper |

| Control method | Industrial computer + 8 axis motion control card | Amplitude modulation method | Software interface electric amplitude modulation |

| Running software | HAIPAI Motion Control Software+Windows10system | Amplitude modulation speed | 250mm/min |

| Programmatically | Teaching/Keyboard and Mouse Sleeves | PCB edge space | ≥5mm |

| Number of spindles | X、Y、Z、U、R 5 axis | Transmission motor | Dual stepper motor control can realize automatic speed adjustment |

| Spindle drive | Servo motor + ball screw module maximum moving speed 600-800mm/sec | Communication port | Standard SMEMA connector |

| Dispensing work scope | X:450mm Y:450mm | Single dispensing width | Optional needles |

| Valve body type quantity | 1 silicone suction dispensing valve H-N02(The capacity of the glue supply system is subject to the glue packaging or customer requirements.) | Equipment air pressure | 0.4~0.6Mpa |

| U、R axis configuration | Servo motor + hollow rotating platform driven rotation | Equipment power supply | AC220V 50HZ |

| Maximum movement speed | 600-800mm/sec | Total equipment power | 1.8kw |

| Maximum height of component | The conveying surface is 110mm above and below | Standard features | LED lighting |

| Spindle repeatability | ±0.02mm | Standard features | Automatic soaking and spitting function |

| Number of tracks | 2 pieces, fixed side forward | Electrostatic interface | |

Honorary Customer

FAQ

Q: What is the conveying height?

A: 910±20mm, please contact the supplier if you have other requirements.

Q: How many spindles are there?

A: X, Y, Z, U, R five axes.

Q: What is the maximum movement speed?

A: 600-800mm/second.

Q: What is a transmission motor?

A: Dual stepper motor control can realize automatic speed adjustment.