01

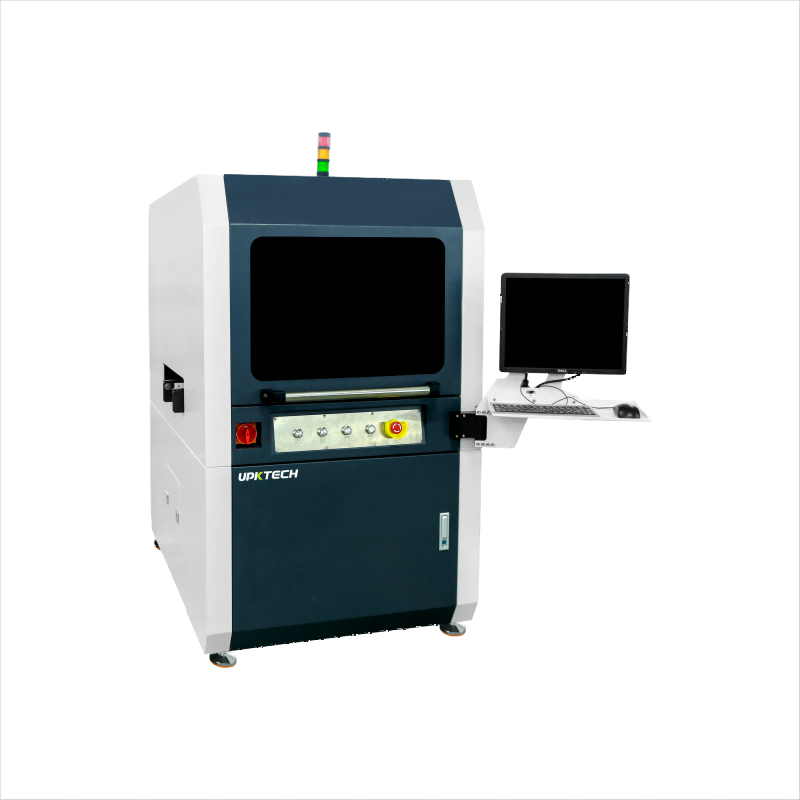

UPKTECH-D30 High-speed Dispensing Machine

01

7 Jan 2019

● Computer control, WINDOWS operating system, fault sound and light alarm and menu display

● Using visual programming, the operation is simple and fast

● X, Y, Z three-axis motion, optional rotating axis (screw valve, injection valve does not need to rotate)

● Using high-performance servo motor + ball screw drive

● The operating accuracy reaches ±0.02mm, and errors can be automatically corrected.

● Integral steel motion plane for smoother operation and programming

● Automatic track width adjustment

● Equipped with high-speed injection valve (200p/s) or screw valve (5p/s)

● Automatic glue valve cleaning device, automatic vacuum cleaning of injection valve

Technical Parameters

| UPKTECH-D30 | |

| Dimensions | L920mm*W1340mm*H1480mm |

| Weight | 1000kg _ |

| Control | Industrial computer + motion control card |

| Max height of component | 5 0mm |

| Programmatically | Online visual programming |

| CCD visual positioning | Automatic calibration of running accuracy |

| X, Y, Z axis drive | Servo motor + precision screw |

| Maximum movement speed | 1000mm / s |

| Repeat accuracy | ± 0.0 1mm |

| Coating stroke | X350 mm, Y 400mm, Z50mm |

| Number of valves | 1 piezoelectric injection valve H -Y01 (nozzle striker can be customized) |

| Paint capacity | 30CC /50CC |

| Input air pressure alarm | Menu + sound and light alarm |

| Power supply | 220V 50~60HZ |

| Air pressure | 6.2kgf/cm2 |

| Total power | 3KW |

| Communication Interface | SMEMA |

| Stepper motor conveying | 2-5m/min |

| Automatic amplitude modulation | Single track: 50 -400mm |

| Remark | ■ Standard equipped with C CD vision camera |

Main Configuration List

|

No |

Product |

Brand |

Qty |

Description |

|

1 |

Industrial computer |

Advantech _ |

1 |

motion control computer |

|

2 |

LCD Monitor |

Dell |

1 |

Human-machine interface display |

|

3 |

Motion control card |

HAIPAI |

2 |

Motion control system , independently developed |

|

4 |

Industrial Network Digital Camera |

Daheng Image/ Hikvision |

1 |

|

|

5 |

Servo motor/Driver |

Fuji |

3 |

Drive related axis motor movement |

|

6 |

Screw nut combination |

TBI |

3 |

|

|

7 |

Photoelectric Sensors |

OMRON |

3 |

PCBA induction |

|

8 |

1/O motherboard |

HAIPAI |

1 |

|

|

9 |

valve body |

HAIPAI |

1 |

Honorary Customer

FAQ

Q: How is the equipment controlled?

A: Our equipment uses industrial computers + control cards.

Q: What is the repeatability accuracy of the equipment?

A: The repeatability of the equipment is ±0.1.

Q: What is the coating stroke of the equipment?

A: Coating stroke X=350mm Y=400mm Z=50mm.

Q: What is the size of the glue supply? Are both 50ML and 30ML acceptable?

A: Yes, both are OK.

Q: Do you provide user manuals and operation videos to support us?

A: We will provide free user manuals and operation videos, and 24-hour online support.