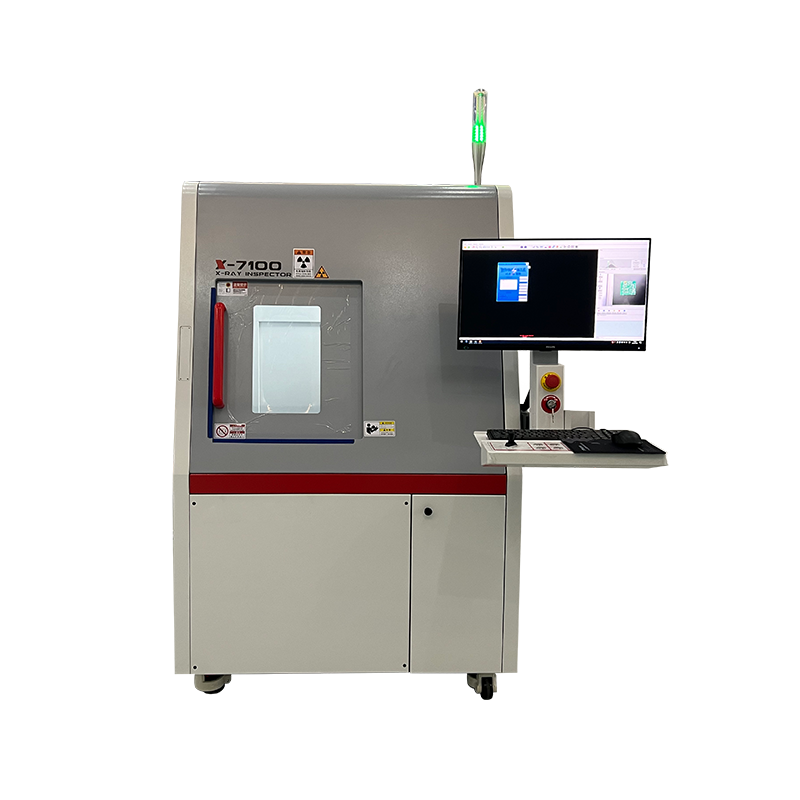

UPKTECH-IR3C Infrared Curing Machine

Technical Parameters

| UPKTECH-IR3C | |

| Dimensions | L 3 000mm*W1080mm*H1300mm |

| PCB transmission height | 9 10 ±20mm |

| Transport speed | 0-3500mm/min |

| Transmission motor | Stepper motor + reducer |

| Conveying method | Chain conveyor (35B5mm extended pin stainless steel chain) |

| PCB width | MAX:450mm |

| Temperature zones | A total of 3 temperature zones |

| Temperature adjustment range | Room temperature - 120 degrees Celsius |

| Heating time | <10 minutes |

| PCB size | MAX: L 450mm* W 450mm |

| PCB component height | MAX:±110mm |

| Opening method | Software interface control, electric lifting |

| Control method | PLC+touch screen control |

| Weight | Approx.530KG |

| Power supply | AC380V, 50Hz, 3-phase 5-wire system |

| Total equipment power | 9.5KW |

Configuration List

|

No |

Product |

Brand |

Qty |

Function |

|

1 |

PLC _ |

Xinjie |

1 |

Furnace temperature control |

|

2 |

touchscreen |

Xinjie 7 inch |

1 |

HMI |

|

3 |

stepper motor |

intelligence |

2 |

Conveying speed and width adjustment |

|

4 |

electric putter |

LYX |

2 |

Used to open and close the curing oven lid |

|

5 |

Temperature PID control module |

FOTEK |

3 |

temperature control |

|

6 |

switching power supply |

Mean we ll/mean well |

2 |

Weak current power supply part |

|

7 |

Heating pipe |

Fine research |

18 |

Heating part |

List of Wearing Parts

|

No |

P/N |

Material name |

Brand |

Qty |

Function |

Normal service life |

|

1 |

4DQ065 |

Fuse |

Chint |

1 |

Electrical box protection |

6 months |

|

2 |

4DQ324/4DQ271 |

U-shaped sensor |

Omron |

1 |

Gear electric eye |

24 months |

|

3 |

4DQ060 /61 |

AC contactor |

Chint |

3 |

Temperature zone start |

24 months |

|

4 |

4JQ133 |

Power switch button |

Red wave |

1 |

switch |

100,000 times |

|

5 |

4DQ092 |

Emergency stop switch |

Rred wave |

1 |

Emergency stop switch |

100,000 times |

|

6 |

4DQ236 |

Electric putter |

Li Yixun |

2 |

Furnace lid lift |

24 months |

Consumables List

|

No |

P/N |

Material name |

Brand |

Qty |

Recommended replacement cycle |

|

1 |

4JQ133 |

Stainless steel chain |

Hengfa |

3 |

12 months |

|

2 |

4JQ056 |

Stainless steel chain buckle |

Hengfa |

3 |

12 months |

|

3 |

4JJ049 |

Large ferry |

Hengfa |

4 |

12 months |

|

4 |

4JJ050 |

Small sprocket |

Hengfa |

4 |

12 months |

Honorary Customer