0102030405

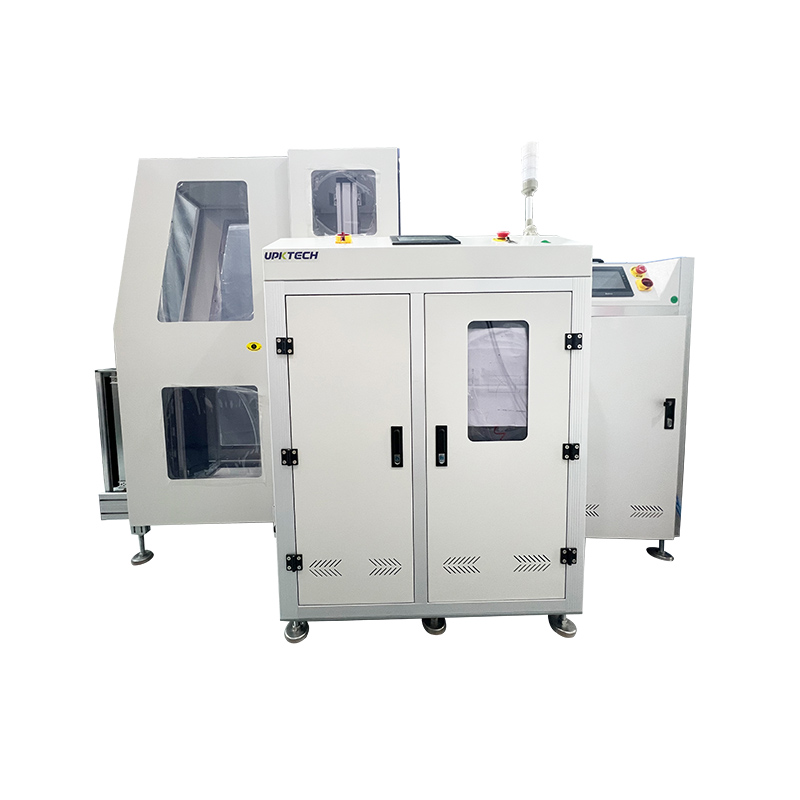

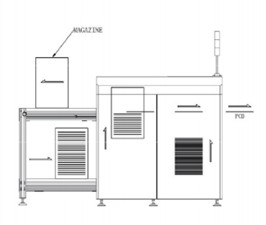

Vacuum Suction Type PCB Loader

01

7 Jan 2019

Special aluminum alloy mechanism for better understanding of Magazine's operating status.

Stable one-piece casting lifting platform structure design, improve the stability of the equipment

Multi-functional electrical circuit and program design, stable performance, to ensure smooth production line.

4 kinds of PITCH selections in the board loading part of the magazine, and the step distance of PCB feeding can be set.

Adopt LED three-color working indicator, 7-inch colorful human-machine interface control.

Suction nozzle positioning adopts universal positioning mechanism, which can be adjusted according to the characteristics of PCB board.

Suction board on the board part of the board storage device with lifting function

The material box adopts engineering flat plastic tape transmission

Adjustable speed control of pushing board

Three-point positioning type up and down pneumatic tightening to ensure the accurate position of the material box.

Push the board protection system to ensure that the PCB board will not be back bad, reduce the process loss

Standard SMEMA communication interface, can be connected with other automation equipment.

Operation Diagram

Technical Parameters

| Content | Parameter |

| Description | This unit is used for automatic loading operation of double-sided boards and transceiver board |

| No.of magazine | Upper Conveyor:1 magazine lower conveyor:2magazine |

| Indexing pitch | 10.20.30.40mm or specify |

| Maximum PCBs capacity | 400pcs(0.6mm thick PCB) |

| Cycle time | Approx.12seconds or specify |

| Powersupply | AC1P110V/220V |

| Power | Max 300VA |

| Air pressure | 4-6bar, 30ltr/min max |

| Transport height | 900±20mm(Or customized) |

| Transport direction | From left to right or right to left |

Specifications

|

Model |

Dimension(L*W*H MM) |

PCB size(MM) |

Rack size(L*W*H,MM) |

Weight(KG) |

|

VL-M-TN |

1800*865*1250 |

50*80-330*250 |

355*320*563 |

200 |

|

VL-L-TN |

2220*945*1250 |

50*80-445*330 |

460*400*563 |

240 |

|

VL-LL-TN |

2450*1110*1250 |

50*80-530*390 |

535*460*563 |

280 |

|

VL-XL-TN |

2450*1250*1250 |

50*80-530*460 |

535*530*563 |

320 |

FAQ

Q. What should I do if I report an abnormal suction vacuum?

A. Check that the suction nozzles are aligned with the holes in the plate, or check if there is any air leakage from the air hose.

Q. What if the reported cylinder is not in place?

A. Pay attention to check whether the sensor on the suction plate cylinder is abnormal or not installed in place.