0102030405

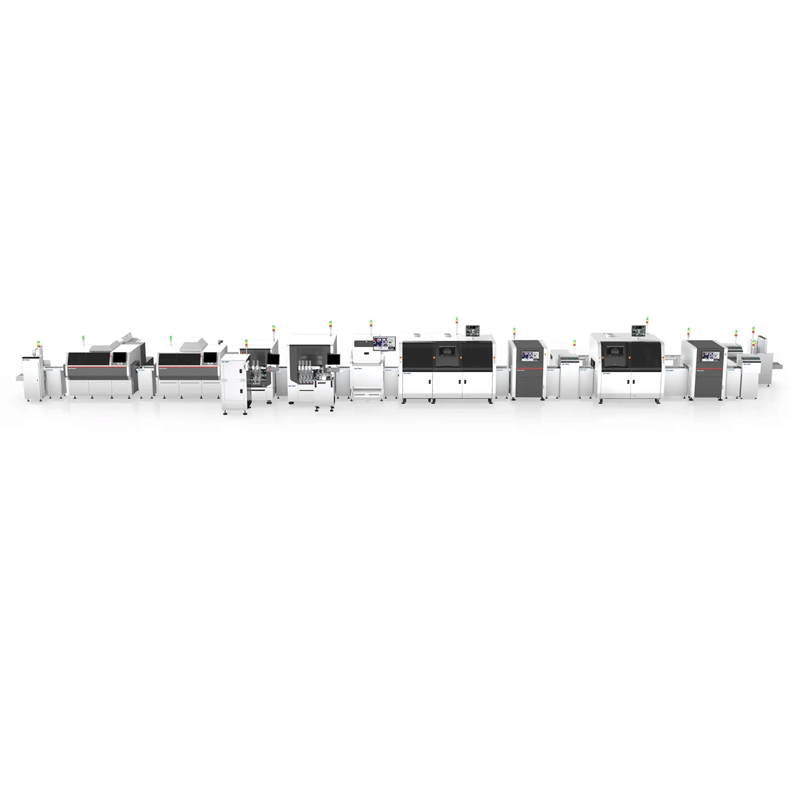

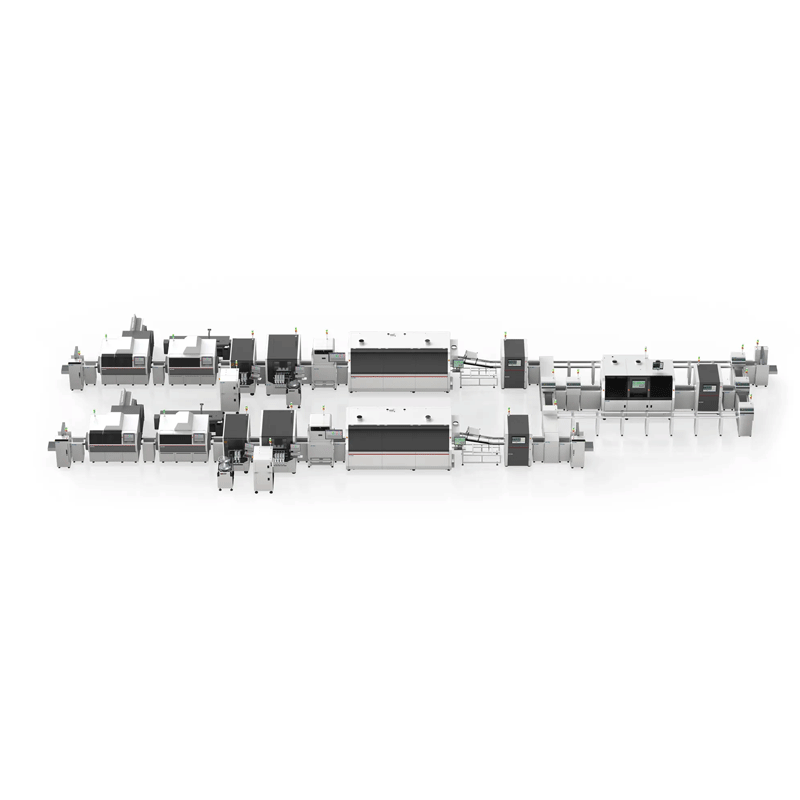

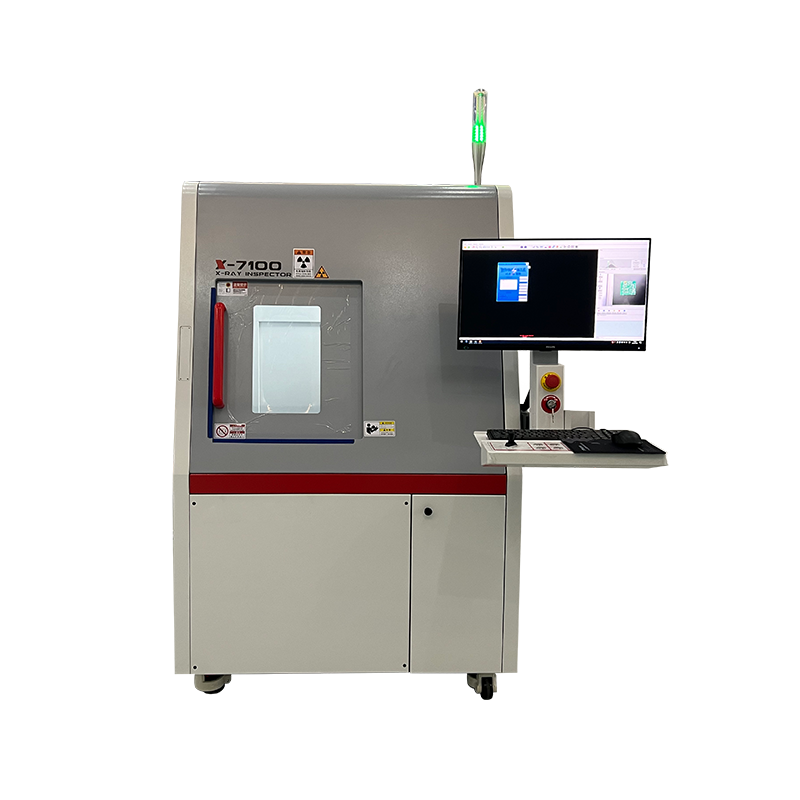

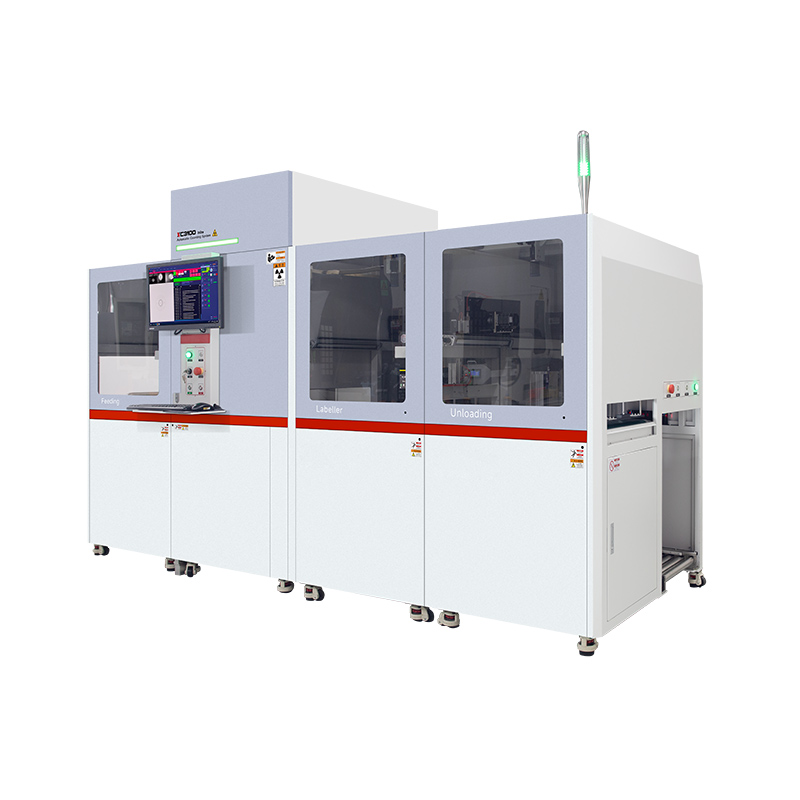

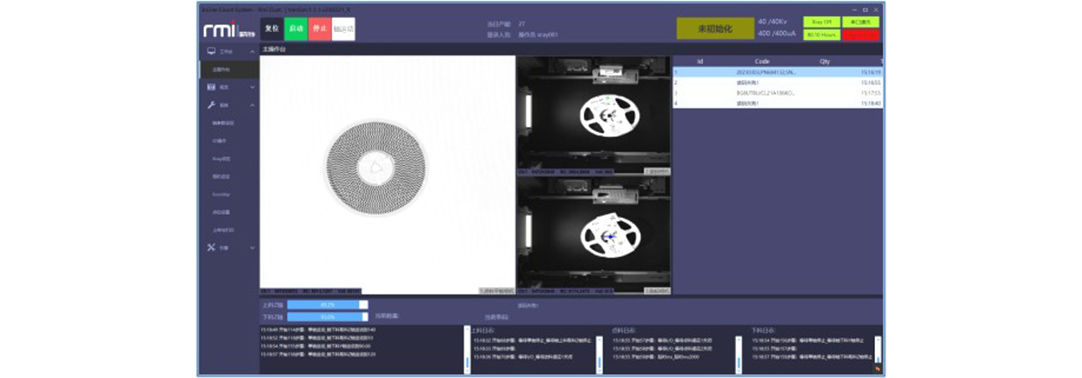

X-ray In-line XC-3100 Counting Machine

01

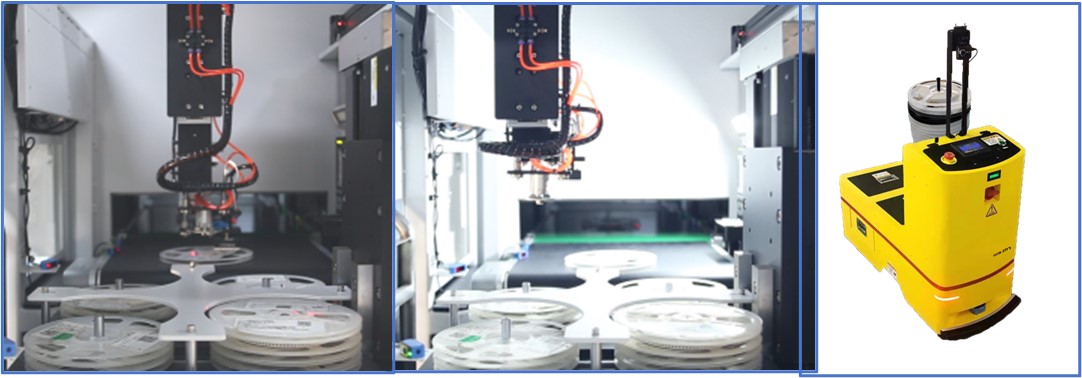

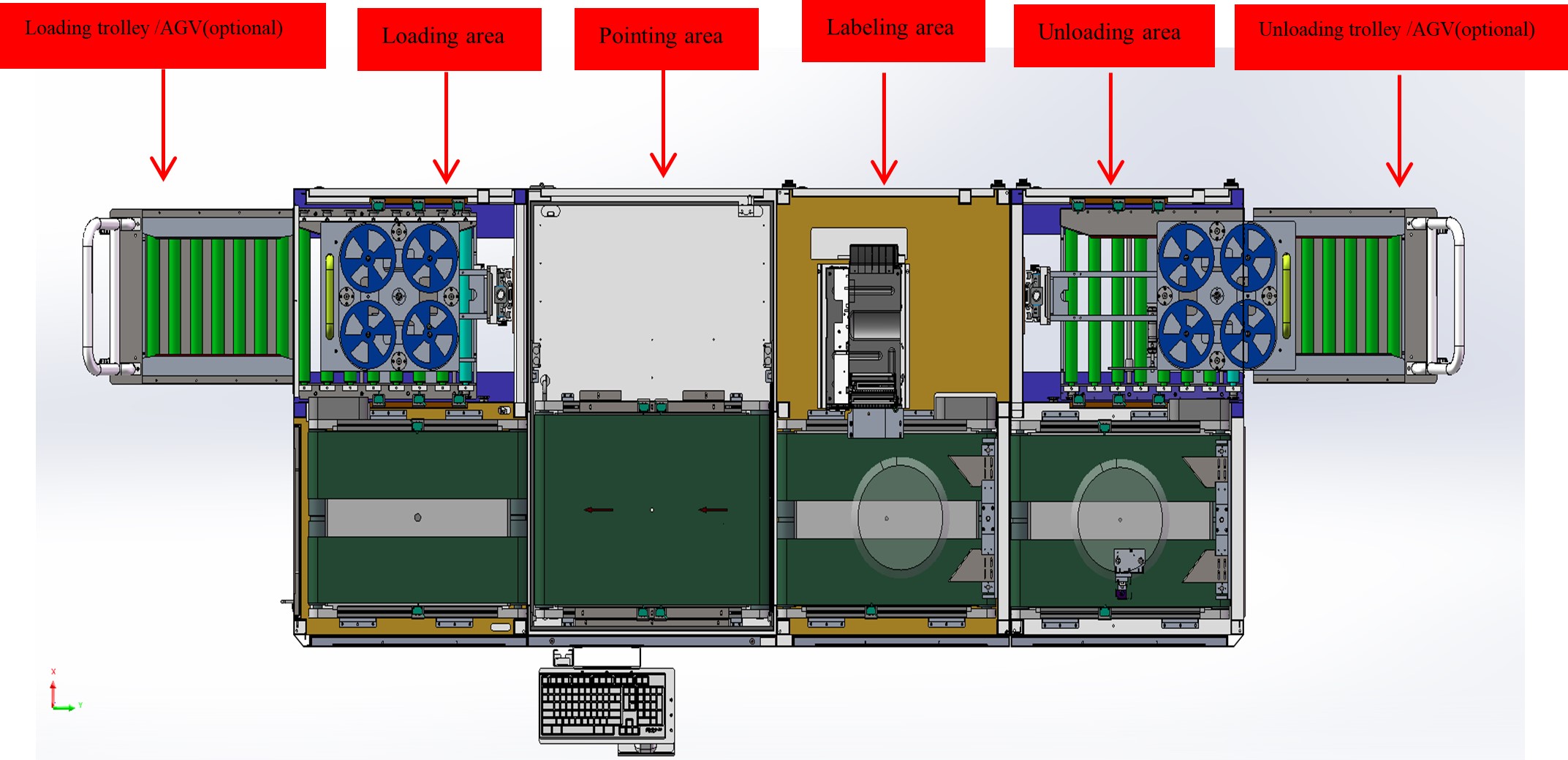

Automatic loading

2018-07-16

With nectar and honey pouch Although I didn't bring a honey jar But there is a honey pouch in the belly of the bee Is specially used to hold nectar

view detail

The materials are put into the loading cart, push the cart into the corresponding position, grab the material tray and put it on the conveyor belt.

01

Automatic pointing and analysis

2018-07-16

With nectar and honey pouch Although I didn't bring a honey jar But there is a honey pouch in the belly of the bee Is specially used to hold nectar

view detail

Send to the loading position, close the warehouse door, tablet automatically takes photos, automatic analysis, points, after successful points, the computer automatically turns off the ray, the quantity of material trays is unloaded to the customer server. Generate new information barcode for tray.

01

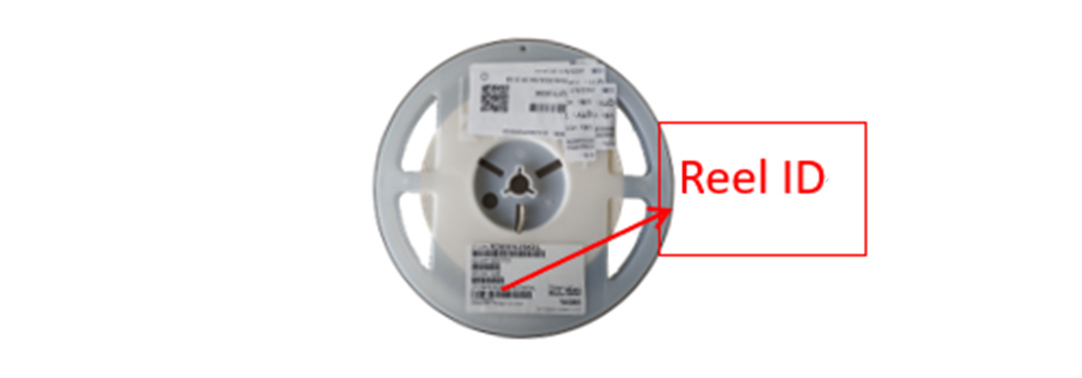

Automatic transcoding

2018-07-16

With nectar and honey pouch Although I didn't bring a honey jar But there is a honey pouch in the belly of the bee Is specially used to hold nectar

view detail

The function of automatically generating unique codes and automatically printing unique codes can automatically generate unique codes based on customer incoming material labels.

01

Automatic unloading

2018-07-16

With nectar and honey pouch Although I didn't bring a honey jar But there is a honey pouch in the belly of the bee Is specially used to hold nectar

view detail

After the ordering is completed, the material tray is discharged from the warehouse. The material tray flows out through the conveyor belt. Take a photo to position it. The new barcode is affixed to the corresponding position with the gripper. After pasting, the new barcode is photographed and positioned. The gripper puts the material tray into the material cart to complete the ordering of materials.

Ordering Flow Chart

Technical Parameters

| Technical Parameters | ||

| Tube | Model | XC-3100-INLINE |

| Tube type | Closed shut pipe | |

| Spatial resolution | 30μm | |

| Tube voltage | 50KV (actual 80KV,limit 50KV) | |

| Tube current | 1000μA | |

| Tablet | Imaging accuracy | 139μm |

| Image size | 430*430mm | |

| Resolution | 3072*3072px | |

| Camera | Imaging speed | 5 EDS/s |

| Code reading pixels | 20 million inches | |

| Tablet | Accuracy | 99.99% (0201 for example) |

| Minimum part size detectable | Imperial 1005 | |

| Operation mode | AI intelligent full warning tracking system | |

| Power supply/power | AC110-220V 50-60HZ 1200W | |

| Radiation safety test | <1uSV/H | |

| Repeatability testing | ≥2.0sigma | |

| Cycle time | ≤15s/time | |

| Structure | Counting speed | 9-15 S/4 reels (CHIP 0201) |

| Machine size | 3087*1194*1957mm(L*W*H) | |

| Machine size (Including keyboard) | 3087*1488*1957mm(L*W*H) | |

| Machine weight | 1500kg | |

| Platform movement mode | Fully automatic loading, ordering, labeling and unloading. | |

FAQ

Q: What to do if the software cannot be started?

A: Turn on the emergency stop and restart the software.

Q: When ordering ingredients, the ordering position is not accurate?

A: a. First check whether the image is clear.

b. Click the inaccurate material three times in a row, take the original image from the D drive-OK file, compress it and send it to the supplier for model optimization. After the model is optimized, the supplier will contact you to update the latest model.

Q: Why does the tablet fail to open?

A: a. Whether the emergency stop is turned on.

b. Whether the tablet network port has been changed and reset the IP 192.168.8.188 (network configuration).

c. Open the back door of the equipment and look at the circuit board to check whether the indicator light of the 12V power supply lights up green normally.

d. The last time the program did not exit and complete, just restart it.

Q: Why does MES upload fail?

A: a. Do not upload mes if the barcode is not read.

Open b.mes software

c. Is the interface address correct?